-

How are mercury emissions controlled in municipal solid waste and sewage sludge incineration processes?

Date posted:

-

-

-

Post Author

Patrick LaveryCombustion Industry News Editor

-

1. Background

Mercury is present in most fuel sources in [GLOSS]trace metal[/GLOSS] amounts, and is volatilised with heat, eventually being emitted in [GLOSS]flue gases[/GLOSS]. From [GLOSS]coal[/GLOSS][GLOSS]combustion[/GLOSS], mercury control presents a particularly difficult problem, but in other processes, control is more manageable. This combustion file is aimed primarily at the incineration of [GLOSS]MSW[/GLOSS] and [GLOSS]sewage sludge[/GLOSS].

Typically, sewage sludge contains between 0.5 and 10 mg/kg (dry weight) mercury, and MSW up to 15 mg/kg. Waste derived fuels can have between 1 and 10 mg/kg dry weight.

Release of mercury from fuel sources begins at ~150 oC, and is complete at temperatures of 500-600 oC. Elemental gaseous mercury is oxidised at temperatures between 300-400oC in the presence of HCl, Cl2, and also NO2.

Further information on mercury can be found in CF59: What are the essential problems relating to mercury emissions from combustion?

MSW and sewage sludge incineration systems have higher concentrations of mercury in their flue gases than coal-fired power plants. Also, flue gas volumes are smaller and velocities are lower, making treatment easier.

Legislation/Regulations/Guideline Limits

Legislation is in place for MSW incinerators in the EU and the US. Guideline values are shown in Table 1. MSW incineration typically produces mercury concentrations in raw flue gases of ~1 mg/m3STP, meaning that reduction of ~90% of total mercury is required.

Table 1. Guideline emission values for mercury from MSW incinerators

|

|

EU (as of 2000) |

USA (as of 1995) |

|

Hg guideline, mg/m3 (STP) Dry at 11% O2 |

0.05 |

0.06 |

2. Control Technologies

Control of mercury emissions from MSW and sewage sludge incineration is usually performed by the gas clean up units already in place for other pollutants. Injections of various agents can be implemented to increase the effectiveness of mercury control if necessary.

In MSW sewage sludge incineration facilities, there are usually two gas clean up devices installed that are often not present in coal-fired power plants. These are HCl scrubbers and SO2 scrubbers. The former is the least common in coal-fired power plants, and also the most effective unit for removing mercury.

HCl scrubbers remove oxidised mercury by dissolving it in the scrubber liquid, which is typically at a pH of ~1. [GLOSS]FGD[/GLOSS] (SO2) scrubbers can have Hg precipitating agents such as TMT (trimercapto-s-triazine) or [GLOSS]Na2S4[/GLOSS] injected to increase their removal efficiency.

It is important to remember that mercury is present in three forms in flue gases: as elemental vapour, in elemental form bound to particles, and finally in [GLOSS]inorganic[/GLOSS] compounds soluble in water. Particle bound Hg can be trapped by [GLOSS]particulate control devices[/GLOSS]; oxidised Hg can be trapped by scrubbers, but elemental vaporised Hg is more difficult to control.

In some cases, it is sufficient to remove just the particle bound mercury and the oxidised mercury. However, if this does not remove enough of the total mercury, then injection of oxidising agents (such as Na2S4, TMT or sodium chlorate) is performed to oxidise the mercury, so that it may be removed. Also, activated carbon (CF188) or other sorbents such as zeolite can be used as a final control utility to adsorb gas phase elemental mercury. These injections are relatively easy to retrofit.

To summarise, the three most important mercury removal processes in MSW and sewage sludge incineration are:

· The acid scrubber for HCl

· Wet scrubbing, with the addition of an oxidising agent if required, to improve capture

· Adsorption onto activated carbon, with the addition of an oxidising agent if required, to improve capture

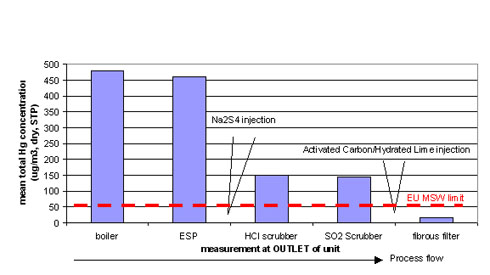

Figure 1 illustrates the effectiveness of the flue gas clean up devices installed in a sewage sludge incinerator for removing mercury. Over 97% mercury reduction is achieved.

Figure 1. Hg removal from a sewage sludge incinerator (Saenger et al., 1999)

Sources

[1] Zevenhoven, R. and Kilpinen, P., Control of Pollutants in Flue Gases and Fuel Gases, Helsinki, 2001

[2] Saenger, M et al., Concentrations and mass balance of mercury in a fluidised bed sewage sludge incineration plant, Proceedings of the 15th International Conference on FBC, Savannah (GA), 1999.