-

Operation of world’s largest IGCC plant begins in Fukushima, Japan

Date posted:

-

-

-

Post Author

Greg Kelsall

-

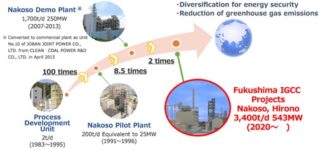

The construction of an integrated (coal) gasification combined cycle (IGCC) plant in Iwaki, Fukushima, has been completed, followed by the formal handover of the plant to the customer, Nakoso IGCC Power GK. Reported by the plants constructor MHI, operation of the high-efficiency, clean, commercial power plant incorporating the world’s most advanced coal gasification technologies, began on 16 April 2021. Mitsubishi Power manufactured the core air-blown IGCC system, including the coal gasification furnace. At 525MW gross capacity, the project represents the world’s largest IGCC configuration, more than twice the scale of the previous 250MW Nakoso Unit 10, completed in 2007. This is the first domestically developed air-blown IGCC system of such a large scale in commercial use. Compared to the Unit 10, power generation efficiency has been substantially enhanced reaching 48% (LHV basis), which was enabled by the high firing temperature of the gas turbines. Key performance data for the plant is shown below, as defined in the Nakoso IGCC website.

The Nakoso IGCC development path

| Capacity | 525MW (gross) | |

| Coal consumption | Around 3400t/day | |

| Efficiency (net) | Around 48% (LHV) | |

| System | Gasifier | Air-blown, dry feed two-stage entrained flow |

| Gas clean-up | Wet (chemical absorption) + gypsum recovery | |

| Gas turbine | Single-shaft (1400℃ -class) | |

| Flue gas properties | SOx | 19ppm (11.6% O2 basis) |

| NOx | 6ppm (16% O2 basis) | |

| Particulate matter | 5mg/m3N (16% O2 basis) | |

Key performance data for the Nakoso IGCC demonstration plant

In brief, coal is first gasified in a gasification furnace at high temperature under high pressure conditions. Sulphur, ash and other pollutants are separated and removed, with the refined syngas used as fuel to drive a gas turbine. The plant operates in combined cycle mode with the gas turbine combined with a steam turbine that operates using the steam generated by a waste heat recovery boiler fuelled by waste gas. Compared to conventional coal-fired power plants, IGCC plants can provide greater power generation efficiency and help to reduce carbon emissions. This could provide plant operators with the flexibility to respond to the needs of power providers to make effective use of resources while simultaneously protecting the environment.

The IGCC plant construction project undertaken by Nakoso IGCC Power GK is intended to contribute to the creation of local industrial infrastructure and hence to the recovery of Fukushima.