-

Drax and Mitsubishi Heavy Industries partner to create the world’s largest BECCS project

Date posted:

-

-

-

Post Author

Greg Kelsall

-

-

![]()

As reported in a recent IFRF blogpost, the UK electrical utility Drax Group aims to build the world’s largest biomass energy carbon capture and storage (BECCS) power plant at its site in North Yorkshire, UK. This involves the retrofit of post-combustion carbon capture to some or all of its four 660MWe biomass-fired boilers (as part of a wider CCS scheme), which were previously converted from pulverised fuel (pf) coal-firing between 2013 and 2018, a step which has already reduced the plant’s emissions, reportedly by over 85%. Drax aims to be carbon negative by 2030, with the first BECCS unit at Drax operational by as early as 2027 capturing and storing around 4MtCO2/year. This could increase to 8MtCO2/year by 2030 assuming two units are retrofitted with CCS.

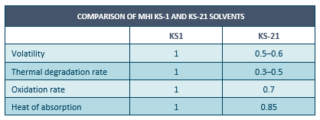

In a significant move to deliver this, Drax has announced that it will partner with Mitsubishi Heavy Industries (MHI) to provide the post-combustion capture system for the first boiler retrofit. As part of the agreement, MHI plans to locate its core CCS team at the company’s European headquarters in London and will be looking at ways to strengthen its supply chain, including the potential production of its proprietary solvent in the UK. Drax has already successfully trialled MHI’s carbon capture technology in a pilot that started in 2020 to test two of MHI’s proprietary solvents KS-1 and the improved KS-21 (see comparison in table below). As reported by MHI, the KS-21 solvent system reduces the capital cost of the amine capture system by 30% relative to the current KS-1 solvent used, for example, at the Petra Nova project in the USA. This is achieved primarily through a 40% reduction in the size of the direct contact cooler, a 30% reduction in the size of the absorber absorption section and a 40% reduction in the size of absorber water wash section. Additional cost reduction is achieved through modularisation, reduced design margins and optimised plant layout. In terms of the solvent itself, a significant reduction in amine thermal degradation is targeted, which allows higher system stripping temperature and pressure to be used, together with reduced compression work.

![]()

Drax has already started the planning process to deploy BECCS at its power station in North Yorkshire – if successful, work could get underway to build BECCS at Drax as soon as 2024.

The project is proposed to connect up with carbon dioxide pipeline infrastructure proposed to be built as part of the Zero Carbon Humber industrial cluster, called H2H Saltend, as covered by IFRF in March. This would see the CO2 generated stored in the Northern Endurance gas field in the southern North Sea.