-

What is the Rayleigh Criterion for Combustion Driven Oscillations?

Date posted:

-

-

Post Author

espadmin

1. What is a Combustion-Driven Oscillation?

A combustion-driven oscillation produces in a process heater or an industrial boiler a marked pulsation of great strength at a specific frequency. It differs from the ubiquitous “[GLOSS]combustion roar[/GLOSS]” (CF6, CF176) that is typical of industrial burners and is, happily, quite rare.

Combustion is an unsteady process that characteristically produces a broadband haystack-shaped sound spectrum that is often referred to as “combustion roar.” On purely theoretical grounds, S. L. Bragg deduced that something of the order of one-millionth of the chemical energy in the fuel is converted to sound. Perhaps that doesn’t sound like much but the heat release of a typical 10-million Btu/hr burner is equivalent to nearly 3-million watts. If something like one-millionth is converted, that gives around 3-watts of sound or in terms of [GLOSS]sound power level[/GLOSS] about 125 [GLOSS]decibel[/GLOSS]s. And a typical industrial furnace might contain up to 40 such burners yielding a prodigious 140 decibels of sound power.

As eddy-like globs of fuel-air burn, the combustion products expand locally and then collapse. This is called by acousticians a “monopole” source which is, unfortunately, the most efficient of the theoretical sources in converting other forms of energy to sound.

We can roughly estimate the period required to consume a typical glob as its diameter (say about 10-2 m) divided by the combustion wave speed (say 0.5-2 m/sec) or 2-10 milliseconds. Inverting this we get 100-500 Hz, so it comes as no surprise that those are the frequencies of ordinary combustion roar.

The natural result of combustion is a low pitched roar easily exceeding the OSHA 90 [GLOSS]dBA[/GLOSS] 8-hour exposure limit. Today we handle this moderately intense sound source with acoustically absorptive burner plenums. But burner plenums that mitigate combustion roar are no help when there arises a rare but much more intense and dangerous source of noise and vibration, combustion-driven oscillation.

2. The Rayleigh Criterion

The general features of “vibrations maintained by heat” (as they were called then) were understood by the mid-1800s. Rayleigh recognized the crucial phase relationship between the communication of heat and the vibration in the resonator. The classical demonstration consisted of a hydrogen flame burning inside an open tube. Pressure variations in the tube cause the flow of gas, and therefore the heat release, volume expansion, and backpressure on the nozzle to vary during the vibration.

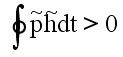

If the product of the fluctuating parts of the backpressure (p) and the heat release (h), integrated over a cycle of the vibration, is positive, in the absence of damping the vibration will be maintained. In other words, if the fluctuating heat release is more in phase than out of phase with the vibration in the resonator, conditions are right for feeding energy into the vibration.

That is often called the “[GLOSS]Rayleigh Criterion[/GLOSS]” and what Rayleigh observed is often referred to as the “singing flame.”

Singing flames are analogous to other, more familiar, self-excited vibrations in which the vibrating system extracts its sustaining energy from another system, usually a flowing stream. Singing telephone cables are a familiar example. The Tacoma Narrows bridge failure is an oft-told classic.

In a singing flame, combustion provides the energy to sustain gas vibrations inside the combustion chamber. Thus, the gas inside the combustion chamber plays the role of the telephone cable, and the heat energy released in the combustion process plays the role of the wind.

3. No “Cookbook” Solutions

In CF296 & CF297 we will illustrate some potential solutions with stories of several of the combustion-driven oscillations that the author has encountered in his career.

Perhaps it is worth reflecting on the question of whether or not, some 125 years ago, John William Strutt (3rd Baron Rayleigh) told us pretty much everything we ever needed to know about the elimination of combustion-driven oscillations, on the rare occasions in which they arise, if only we have the patience to listen intently and interpret correctly. The author thinks that he did.

However, Rayleigh did not provide a “cookbook” of solutions. The “… have the patience to listen intently and interpret correctly …” phrase in the foregoing paragraph is important. Resolution of combustion-driven oscillations, on the rare occasions in which they arise in the field, is usually an experimental “cut-and-try” process in which the wise practitioner relies on Rayleigh’s 125 year old advice and guidance.

Charles Vernon Boys, like John William Strutt (3rd Baron Rayleigh), was a famous British researcher and a Rayleigh contemporary. In a lecture at the London Institution in 1889, Boys explained why we do experiments.

“… when we want to find out anything that we do not know, there are two ways of proceeding. We may either ask somebody else who does know, or read what the most learned men have written about it, which is a very good plan if anybody happens to be able to answer our question; or else we may adopt the other plan, and by arranging an experiment, try for ourselves. An experiment is a question which we ask of Nature, who is always ready to give a correct answer, provided we ask properly, that is, provided we arrange a proper experiment.”

So what? Well, no matter who the expert, at least some experimentation will be involved in suppressing any combustion-driven oscillation should you be so fortunate as to encounter one. It is good to ask somebody who knows and to bring a qualified expert aboard. IFRF can help identify such individuals who will be able to help you. At least a qualified expert knows what questions to ask of Nature and how to ask them. But Rayleigh didn’t provide a cookbook. Not even to experts.

In cobbling-up CF295, 296 and 297 and reflecting on solutions ultimately found in my experience and the experience of others, I’m reminded that many years ago my friend Abbott Putnam shared with me an early AGA (American Gas Association) field-service bulletin that included a prescription for eliminating combustion-driven oscillations in home heating units; viz., “Drill a hole; if that doesn’t work, drill another hole …” or words to that effect. Many times have I wished that I still had a copy of that bulletin and in this paper we will have occasion, once again, to reflect upon the value of that advice in eliminating combustion-driven oscillations.

And what about ensuring, at the design stage, the absence of combustion-driven oscillation in the field? That is an entirely different proposition. Frankly, the author doesn’t have a clue and he is pretty sure that John William Strutt (3rd Baron Rayleigh) didn’t have a clue either.

Note from the Editor in Chief: There are a number of analytical approaches that help in specific circumstances, and I’m sure the author knows more about them than he admits to. We will try to cover them in future Combustion Files (see for example CFs 296 and 297 by same author). Generic solutions for all plant at the design stage are still beyond us.

Sources

[1] John William Strutt, 3rd Baron Rayleigh, Sc.D., F.R.S., Honorary Fellow of Trinity College, Cambridge; The Theory of Sound, §322h, 1878

[2]Jim Seebold Combustion-driven Oscillation in Process Heaters, IFRF Combustion Journal , 2005

[3] Jim Seebold Combustion-driven Oscillation in Process Heaters. AFRC-JFRC 2004 Joint International Combustion Symposium, October 2004, Maui, HI. Proceedings CD AFRC Technical Secretary (Jordan Loftus (afrcjl@earthlink.net) at the time of writing)

[4] Jim Seebold The Author’s experience