-

What is Life Cycle Assessment (LCA)?

Date posted:

-

-

Post Author

espadmin

1. Introduction

[GLOSS]Life cycle assessment[/GLOSS] ([GLOSS]LCA[/GLOSS]) is the process of quantifying the material and energy flows and potential environmental impacts of technological systems. Roots of the [GLOSS]life cycle concept[/GLOSS] can be traced back to the 1960s, when its forerunners, net energy analysis and resource and environmental profile analysis, were developed. Since the 1990s, LCA has developed further through efforts of the Society of Environmental Toxicology and Chemistry [1] and, more recently, the International Organization for Standardization. Current international LCA standards are described in the ISO 14040 series [2 – 5].

LCA has some key distinguishing features. First, all analysis is based on a predefined quantity of product or service called the [GLOSS]functional unit[/GLOSS]. As most LCAs are comparative in nature, the functional unit provides a logical basis for comparing the environmental performance of alternatives. For example, in the LCA of power generation systems a suitable functional unit would be 1 kW-h of electricity. A second characteristic of LCA is that the both direct and indirect environmental effects of the system being studied are assessed. Major activities in the entire product chain – from the cradle to the grave – are included. In the case of electricity generation, for instance, environmental impacts arising from fuel extraction, storage and delivery are included along with direct power plant emissions. Finally, LCA relies on a multiple criterion perspective by quantifying different forms of environmental impact such as global warming, acid rain formation and ozone depletion.

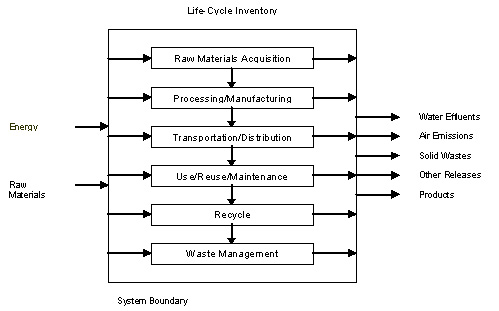

Figure 1. Life cycle system of a generic product [1]

Figure 1 shows the schematic of a generic life cycle. Although the stages shown apply to the case of a manufactured product, the concept is easily extended to include other products (such as heat or electricity) and services. The four components of LCA are discussed in the next four subsections.

Goal and Scope Definition

Goal definition involves identifying the specific purpose of the LCA and the end-user of the information generated in the study [2, 3]. In most cases, LCA involves quantitative or qualitative comparison of alternative technologies. The results can be used to aid different levels of decision-making in scientific, corporate or public policy applications. Scope definition involves identifying the system boundary (i.e., processes to be included as part of the entire life cycle system), the functional unit, and assumptions specific to the system being assessed. The level of detail of the LCA is also defined, for example by identifying the pollutants to be assessed [3]. In practice it may also be possible to “streamline” or simplify the LCA. This concept is discussed in Section 2.

[GLOSS]Life cycle inventory analysis[/GLOSS] (LCI)

LCI consists of material and energy balance computations for the system under study [3]. The final output is the quantity of natural resources consumed and pollutants generated throughout the system per functional unit. A comprehensive treatment of the computational aspects of LCI is given by Heijungs and Suh [6]. These computations are normally performed with the aid of computers, using generic tools such as spreadsheets or dedicated LCA software. The input data used for LCI calculations can be derived from a variety of sources, including:

· Site-specific or company-specific measurements

· Theoretical material and energy balances

· Data from technical and scientific publications (e.g., journal articles or handbooks)

· Electronic databases embedded in LCA software or found in websites

· Expert estimates

In addition to LCI data, information on data quality (i.e., statistical uncertainty, data age) should be collected as well, to put the LCI results into proper perspective.

[GLOSS]Life cycle impact assessment[/GLOSS] (LCIA)

The next step in LCA is to determine the environmental impacts of the different natural resource and pollutant streams quantified during LCI [4]. Suppose that NO2 and SO2 emissions of a given system are estimated to be 1 and 0.5 g per functional unit, respectively. LCIA is carried out through the following steps:

· Classification – identification of environmental impacts caused by each pollutant. For example, both NO2 and SO2 contribute to acid rain formation and some degree of direct effect on human health. In addition, NO2 is also involved in the formation of photochemical smog.

· Characterization – quantification of the extent to which each pollutant contributes to different environmental impacts. This step is accomplished using standard characterization factors. In this example, the acidification potentials of NO2 and SO2 based on proton formation potential are 0.7 and 1.0 g SO2 equivalent per gram. Thus the total acid rain formation potential of 1 g of NO2 and 0.5 g of SO2 is (1 ´ 0.7) + (0.5 ´ 1) = 1.2 g SO2 equivalent per functional unit. Other examples of standard characterization factors are global warming potentials (measured in CO2 equivalents) and ozone depletion potentials (measured in CFC-11 equivalents). Characterization can be extended further, by normalizing the resulting impact values relative to an external benchmark. One approach is to use as a benchmark the average global per capita environmental impact; this procedure has the advantage of reducing all the environmental impact scores to the same measurement unit, the person-equivalent.

· Valuation – comparative LCA implies the need to rank alternative technologies in order to identify the best environmental option. Unless one of the alternatives proves to be superior to its competitors in all respects, the selection problem will involve making tradeoffs. Using weighted averaging to derive a single composite environmental score for each alternative can facilitate the procedure. However, there is still considerable controversy about the valuation of appropriate weight factors, and this aspect of LCA methodology remains the subject of considerable research.

Interpretation

The final step in LCA is the interpretation of LCI and LCIA results. This stage requires careful consideration of all the information used, including data quality; for some applications external peer review is also recommended [5].

2. Related Methods

Full LCA is highly data-intensive, and in some applications it is advantageous to use the life cycle concept without going through the rigors of a complete LCA. Simplified methods are generally known as streamlined LCA (SLCA). LCA can be streamlined using any of the following techniques [7]:

· Using surrogate or proxy data

· Limiting the number of resources, pollutants or environmental impacts analyzed

· Adjusting the system boundary to reduce the number of processes analyzed

· Eliminating some steps, such as detailed impact assessment

· Using qualitative information to supplement or replace numerical data

Use of SLCA entails loss of information that may result in conclusions differing from those produced by a full LCA. Thus, the choice of streamlining technique should take into account the objectives of the LCA and the nature of the systems being analyzed. SLCA techniques are nevertheless potentially useful, particularly as screening tools in preparation for subsequent detailed LCA.

3. Applications in Energy and Combustion

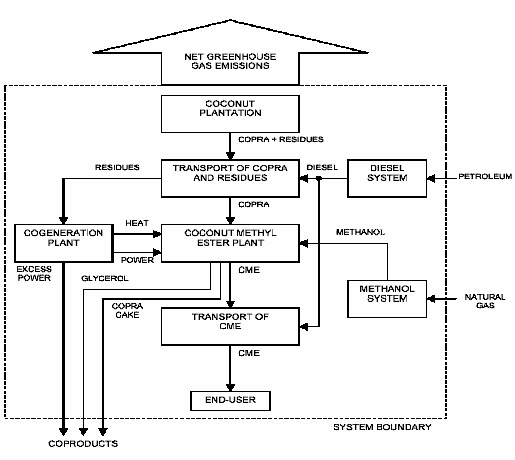

The use of life cycle assessment for energy systems is illustrated by the following example, which deals with the life-cycle CO2 emissions of biodiesel from coconut [8]. Figure 2 shows the schematic of the biodiesel system, while Table 1 shows results for two different scenarios of agricultural residue utilization. CO2 emissions are reported based on 1 MJ of energy delivered by the fuel product. Note that a range of values is given for each scenario; this imprecision arises due to uncertainties in the data used to construct the LCA model.

Figure 2. Coconut Biodiesel Life Cycle [8]

Table 1. Life-Cycle CO2 Emissions of Biodiesel System [8]

|

Scenario |

Net CO2 Flow (g/MJ) |

Reduction* (%) |

Description |

|

1 |

16.3 – 18.2 |

81 – 83 |

Residues used to meet heat requirement of biodiesel plant; process electricity requirement is supplied from the grid |

|

2 |

6.5 – 8.6 |

91 – 93 |

Residues used to meet all energy requirements of biodiesel plant; no export of excess power |

*Relative to conventional diesel

There are many opportunities for the use of LCA and related techniques in the field of energy and combustion. Some key points of interest include:

· As power plant pollution control technology improves, the contribution of other life cycle stages to total system emissions increases.

· SLCA techniques focusing on energy, exergy and greenhouse gas flows are particularly appropriate for energy systems.

· LCA is essential for the analysis of novel energy technologies (e.g., fuel cells) whose commercialization entails considerable investment in capital. LCA provides a framework for estimating the environmental impacts of such technology transitions.

Sources

[1] Society of Environmental Toxicology and Chemistry. “A Technical Framework for Life Cycle Assessments.” Pensacola, 1991.

[2] ISO 14040. “Environmental Management – Life Cycle Assessment – Principles and Framework.” International Organization for Standardization, Geneva, 1997.

[3] ISO 14041. “Environmental Management – Life Cycle Assessment – Goal and Scope Definition and Inventory Analysis.” International Organization for Standardization, Geneva, 1998.

[4] ISO 14042. “Environmental Management – Life Cycle Assessment – Life Cycle Impact Assessment.” International Organization for Standardization, Geneva, 2000.

[5] ISO 14043. “Environmental Management – Life Cycle Assessment – Life Cycle Interpretation.” International Organization for Standardization, Geneva, 2000.

[6] Heijungs, R. and Suh, S. “The Computational Structure Of Life Cycle Assessment.” Kluwer, Dordrecht, 2002 (ISBN 1-4020-0672-1).

[7] Society of Environmental Toxicology and Chemistry. “Streamlined Life-Cycle Assessment: A Final Report from the SETAC North America Streamlined LCA Workgroup.” Pensacola, 1999.

[8] Tan, R. R., Culaba, A. B. and Purvis, M. R. I. ”Carbon Balance Implications of Coconut Biodiesel Implications in the Philippine Automotive Transport Sector.” Biomass and Bioenergy 26: 579 – 585, 2004 (ISSN 0961-9534)