-

How may the IFRF Isothermal Plug Flow Reactor be used to measure char Burnout?

Date posted:

-

-

Post Author

espadmin

1. Background

Usually every coal user has his/her own envelope of required coal characteristics that provide safe operation. These characteristics include rate and yield of [GLOSS]volatile matter[/GLOSS] release, fuel-nitrogen release and [GLOSS]char[/GLOSS] burnout rates. Char burnout rates are important in utility boilers since they affect the total residence time necessary to combust the fuel completely. This influences the boiler water wall height, furnace residence time, heat flux profile along the furnace, the boiler efficiency and the usability of [GLOSS]fly ash[/GLOSS].

The IFRF Isothermal Plug Flow Reactor (IPFR) may be used to investigate those combustion characteristics of pulverised coal and other solid fuels and their chars under a number of well-controlled specific environments.

The reactor enables the coal to be evaluated at a wide variety of residence times under variable particle heating rates and combustion atmospheres. This flexibility enables the combustion performance of the coal to be studied under client/applications specified atmospheric conditions.

Concepts of fuel characterisation are described in CF48. The advanced general concept using the IPFR is described in CF135.

2. Char burnout measurements

Char production

In order to investigate char burnout, fuel chars have to be produced under conditions found in industrial flames. In particular high heating rates in the order of 104 – 105 K/s and the final temperature are very important parameters. To achieve those conditions the IPFR is operated with a wall and flue gas temperature of 1200 °C and an oxygen free atmosphere. Fuels are injected [GLOSS]isokinetically[/GLOSS] in the reactor using inert nitrogen as the carrier gas. Chars are then collected after a residence time of approximately 250 ms in cyclone system. This procedure guarantees that all volatiles are released without exposing the residual char to high temperatures for a significant period of time, which may change its [GLOSS]organic[/GLOSS] structure and cause [GLOSS]thermal annealing[/GLOSS].

Char combustion

For char combustion trials the IPFR can be operated in a temperature range between 900 °C and 1450 °C and oxygen concentrations varying from 5 % to 12 %-vol. Char produced as mentioned above is re-injected isokinetically into the IPFR at several injections ports to vary the particle residence time in the reactor. The residual char is rapidly quenched with molecular nitrogen at the furnace exit to avoid further reaction and sampled in a cyclone system. Solid samples collected that way are used for further analyses.

Determination of char burnout

Char burnout is determined by balancing the actual and initial combustible matter U (unburnt fraction) of the char particle:

|

Eq. (1) |

where X = char burnout [wt.-% daf]

Uact = unburnt fraction of the sample[wt.-% dry]

Uini = unburnt fraction of the initial char [wt.-% dry]

Assuming the particles ash to be completely inert during combustion, ash can be used as a tracer and Equation (1) can be re-written:

|

|

Eq. (2) |

where ash = ash fraction of the sample [wt.-% dry]

It can be seen that the char burnout at various stages of combustion can be determined by performing ash measurements of the samples.

Measured char burnout data together with IPFR operational data residence time, temperature and oxygen concentration can be used to determine kinetic parameters for char combustion sub-models in CFD codes which are essential to predict boiler performance and carbon in ash levels found in the fly ash accurately.

3. Char burnout of El Cerejon char

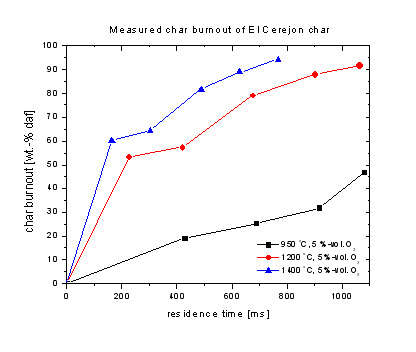

Figure 1 shows typical burnout curves of El Cerejon char measured in the IPFR. Although there was extensive research done in past decades, the heterogeneous reactions occurring during char combustion are still not fully understood, making measurements essential.

Figure 1: Weight loss during char burnout of El Cerejon char

Measurements performed in the Isothermal Plug Flow Reactor can both be used to investigate the nature of the heterogeneous char – oxygen reaction as well as to assess practical parameters used for burner and furnace design.

4. Conclusions

Chars can be produced and char burnout can be measured in the IPFR under conditions found in industrial flames. Data gained in the IPFR contain important information about the expected fuel conversion in a real boiler and can be used to validate combustion models for burnout predictions in CFD models.

Acknowledgements

The author would like to acknowledge the contributions of a long list of IFRF investigators who have worked to develop this reactor during the last fifteen years.

Sources

[1] Haas, J., Maalman, T., Gallagher, G.,: Pulverised fuel combustion characterisation of coal blends, IFRF Doc No F37/y/38, 1997

[2] Haas, J., Lockemann, S., van de Kamp, W.: Combustion characterisation for a suite of different coals, IFRF Doc No F37/y/35, 1995

[3] Knill, K. J., Maalman, T., Morgan, M.: Development of a combustion characterisation technique for high volatile bituminous coals, IFRF Doc No F88/a/10, 1989