-

How do I estimate the effect of beneficiation on the efficiency of BFG fired furnaces relative to natural gas firing?

Date posted:

-

-

-

Post Author

Neil Fricker

-

1. Background

[GLOSS]Blast Furnace Gas[/GLOSS] ([GLOSS]BFG[/GLOSS]), a by-product of iron making (CF 218), is often available as an alternative to bought-in fuels on integrated iron and steel works. Because of its low [GLOSS]calorific value[/GLOSS] (about 1/10th of Natural Gas), it may be necessary to apply one or more beneficiation techniques in order to apply BFG as a fuel for high temperature furnaces (CF 249).

This combustion file presents a graphical empirical method of estimating the relative (to [GLOSS]natural gas[/GLOSS]) firing efficiency of a high temperature furnace operating on BFG. It is based on the observations made at the IFRF during the G1 Furnace Trials [1].

2. Conditions for which the correlations apply

The G1 trials were undertaken on an IFRF test furnace with the following characteristics;

· Furnace 2mx2mx6.5m

· Heat input 1.5 to 3 MW (fuel plus preheat)

· Heat extraction to load 150 to 300 kW/m2

· Combustion intensity 60 to 120 kW/m3

· [GLOSS]Excess air[/GLOSS](or oxygen) 10%

· Air and/or fuel preheat up to 500oC

· Oxygen concentration in the [GLOSS]comburent[/GLOSS] from 21% (air) to 50% by volume

· BFG [GLOSS]Lower Calorific Value[/GLOSS] 2.3 to 3.1 MJ/kg

· Natural Gas Lower Calorific Value 44 MJ/kg (7,2% inerts, 85% methane)

3. Efficiency correlations

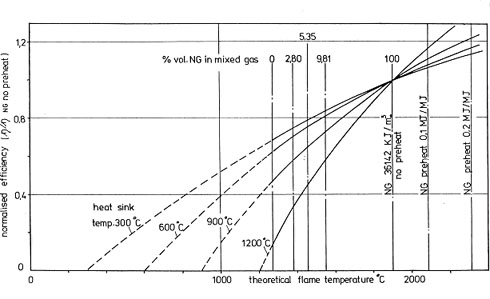

In Figure 1, the efficiency (relative to the same furnace fired on natural gas with no air preheat) of a BFG fired furnace is presented as a function of the [GLOSS]adiabatic flame temperature[/GLOSS] of the fuel used. The relative efficiency curves are given for four different load temperatures. Other values may be estimated by interpolation.

Values of the adiabatic temperature for BFG with natural gas addition are represented directly on Figure 1 by vertical dotted lines. The effect of two levels of air preheat on the adiabatic flame temperature of the natural gas fired furnace is also represented by two additional vertical lines. A more extensive relationship between adiabatic flame temperature, fuel and air preheat, natural gas addition and [GLOSS]oxygen enrichment[/GLOSS] is given in linked combustion file CF 251.

Figure 1 Relative efficiency of a high temperature furnace fired on Blast Furnace Gas at different load temperatures

These correlations are curves based on a single equation:

E/Eo (Ts) = [(Tf – Ts)/(Tfo – Ts)]a ………….. (1)

where:

E/E0 is the furnace efficiency relative to the same

furnace operating with natural gas

Ts is the load temperature (oC)

Tf is the adiabatic flame temperature of the BFG

with benefaction (oC)

Tfo is the adiabatic flame temperature of natural

gas = 1900oC

a is an empirical dimensionless constant = 0.78 +/- 0.06

This equation may be used in place of Figure 1 if required.

4. How do I use the correlation in Figure 1?

In order to estimate the effects of beneficiation on furnace efficiency, it is first necessary to determine the adiabatic flame temperature of the BFG with beneficiation. For BFG and natural gas blends with no other beneficiation applied, the adiabatic flame temperature and the relative efficiency may be read directly off Figure 1 using the vertical lines representing % by volume natural gas enrichment ( Note: IFRF was using a natural gas containing 8% inerts). Linked Combustion File CF 251 presents the approach used by the IFRF to estimate the adiabatic flame temperature for a wider range of beneficiation techniques.

Once the adiabatic flame temperature is known, use the load temperature curves in Figure 1, interpolating for the required load temperature, to estimate the relative efficiency of the furnace.

Figure 1 may also be used to estimate the effect of air or fuel preheat on the initial efficiency of a natural gas fired furnace, and this should be taken into account when applying Figure 1 to furnaces employing preheated air when firing natural gas

5. Worked example

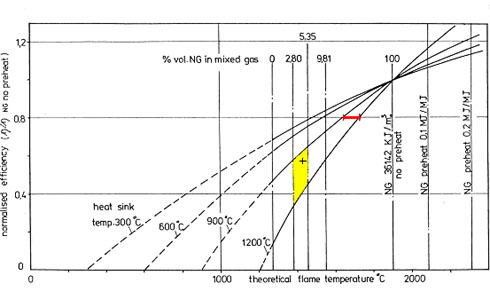

What will be the relative efficiency (compared to natural gas firing) of a furnace firing BFG that contains 4.5% methane, (equivalent to about 5% natural gas addition)? What adiabatic flame temperature would be needed to increase the relative efficiency to 80%? Furnace load temperature is 1000oC.

Using Figure 1, the vertical lines corresponding to natural gas addition at 2.8% and 5.35%, together with the heat sink temperature curves for 900oC and 1200oC define the region within which the relative efficiency will lie (Yellow region, Figure 2). This will be between 35% and 60%. By interpolation, a better estimate of the relative efficiency is 50 +/- 5%.

In order to increase this value to 80%, the points at which the load temperature curves for 900oC and 1200oC cross the 0.8 relative efficiency line (red bar, Figure 2) indicate a required adiabatic flame temperature of between 1640oC and 1720oC. Interpolation refines this value to 1660+/-15oC.

Figure 1 also indicates that to achieve such a temperature will require significantly more than 10% natural gas enrichment. Other options to achieve the temperature through the use of oxygen enrichment, air and fuel preheat, additional natural gas enrichment or a combination of all three may be assessed using the correlations presented in CF 251.

Figure 2: Example of use of Figure 1

Acknowledgements

The author acknowledges the support and encouragement of Jean-Bernard Michel and Roy Payne during the adaptation of their original report to create this Combustion File.

Sources

[1] Michel J-B and Payne R. The use of blast furnace gas as a fuel in high temperature furnaces of the steel industry. Final report of the IFRF G1 trials, IFRF Doc No F01/a/100, March 1979.