-

Vicat deploys carbon capture at Montalieu cement plant in France

Date posted:

-

-

-

Post Author

Philip SharmanIFRF Director

-

-

![]()

Globally, the cement industry is responsible for 5-7% of greenhouse gas emissions. As a result, significant research, development and demonstration is underway looking at a number of pathways to reduce these emissions, including efficiency improvements, switching to lower-carbon fuels, using alternative materials in the production process, and carbon capture, utilisation and storage (CCUS).

The French-based Vicat Group has an industrial tradition dating back to 1817, when Louis Vicat invented an artificial cement. Now, over 200 years later, Vicat (established by Louis in 1853) operates in twelve countries, with some 64% of its sales generated outside France, and with core lines of business in cement, ready-mixed concrete and Aggregates, as well as related activities.

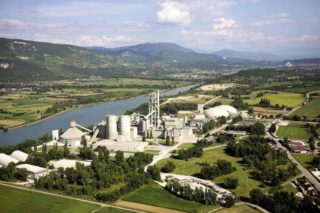

As part of its commitment to be carbon neutral by 2050, the Vicat Group cement company has considered a number of different approaches to tackle its carbon emissions, and in August deployed a pioneering technology to capture and utilise carbon dioxide at its Montalieu cement plant near Lyon in southern France.

It has signed a commercial agreement with Carbon8 Systems, a UK company that has invented and owns a process that combines industrial waste residues or by-products with captured carbon dioxide emissions to produce high-value, lightweight construction aggregates.

Montalieu is Carbon8 Systems’ first commercial deployment of its ‘CO₂ntainer’ system (a modular, containerised solution) in Europe and follows successful demonstration projects at cement plants in the UK and Canada.

The CO₂ntainer will be deployed directly onsite at Montalieu and integrated into Vicat’s existing industrial processes. Crucially, it will capture carbon dioxide directly from the plant’s flue gas emissions, which will be used to convert cement bypass dust into lightweight aggregates through the use of Carbon8 Systems’ patented Accelerated Carbonisation Technology (ACT) solution. The ACT process mineralises and stabilises this dust to produce a granular solid which can be utilised in producing aggregates for construction.

In its first phase of operation, Carbon8 Systems’ CO₂ntainer will process and convert up to 12,000 tonnes of cement bypass dust into valuable construction aggregates. Vicat can commercially repurpose the aggregates in various applications, for instance in lightweight concrete blocks.

“As part of our commitment to limit our environmental impact, Vicat has looked at a number of innovative ideas to reduce its carbon emissions,” said Dr Laury Barnes-Davin, Scientific Director of Vicat. “We are attracted by Carbon8 Systems’ two-part technology proposition: capturing the CO₂ that Montalieu emits and using it to produce an aggregate that can be marketed to industry. We are excited by its potential for our operations elsewhere in France and around the world.”

Carbon8 Systems is in advanced discussions with other cement companies around the world to deploy its CO₂ntainer solution.

Dr Paula Carey, co-founder and Technical Director of Carbon8 Systems, said: “Securing a commercial agreement with Vicat, a family-run cement company that has been in business for more than 150 years and with a strong commitment to process innovation and sustainability, is a massive endorsement of our technology and the R&D work that we have carried out over recent years. We are delighted that Vicat has chosen Carbon8 Systems to help reduce its carbon emissions and, at the same time, create a potential new income stream for their business.”

In addition, Carbon8 Systems is pursuing opportunities in other sectors where waste residue disposal is increasingly expensive and carbon dioxide emissions need to be reduced as part of the transition to net zero by 2050. By utilising the waste at source and onsite, companies using ACT will reduce the amount of waste going to landfill, so further reducing the environmental impact of their operations.

Dr Paula Carey added: “Carbon8 Systems is a true circular economy company and the ‘only game in town’ for successful and sustainable decarbonisation of industrial residues.”

In addition to cement, other sectors where ACT can be used include power generation (energy-from-waste) and the steel and paper industries.