-

Siemens Energy signs agreement to build waste-heat-to-power facility in Canada

Date posted:

-

-

-

Post Author

Greg Kelsall

-

-

![]()

Siemens Energy has signed an agreement with Canadian company TC Energy to commission a novel waste-heat-to-power pilot plant in Alberta, Canada.

The facility will capture waste heat from a gas-fired turbine, operating at a pipeline compression station, to produce emissions-free power. According to the developers, the electricity produced will result in estimated greenhouse gas reductions of 44,000 tonnes per year. As part of the agreement, the Houston-based arm of Siemens Energy will build, own and operate the facility, with the option for ownership to be transferred to TC Energy at a later date.

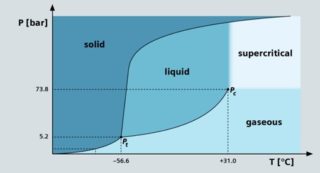

The core of the project is an innovative heat recovery process designed by Siemens Energy. The patented technology, licensed under Echogen®, is based on an advanced Rankine Cycle and uses supercritical carbon dioxide (sCO2) as the working fluid to convert waste heat into power. The new heat recovery system utilises the unusual properties of CO2 when it is compressed to pressures in excess of 73.8 bar at temperatures higher than 31°C. Under these conditions, it has a consistency like a viscous liquid, whilst flowing easily like a gas. An increase in the physical density of the working medium without impeding its flow properties increases its power density and therefore the electricity produced.

![]()

CO2 is supercritical at pressures about 73.8 bar and temperatures above 31°C

The high power density of the sCO2-based heat recovery system can be used for more than just increasing electrical output in applications that currently use steam turbines. It also makes it possible to construct turbines that need significantly less build space than steam turbines offering the same output. This gives potential benefits for the sCO2 turbomachinery of :

- 25-40% smaller footprint than steam-based systems

- 10% increase in compressor station efficiency

- capability to produce clean, emissions-free electricity.

In industrial retrofit applications, the smaller footprint would be a particular advantage where there may not be the physical space to install a steam turbine.

The pilot project at TC Energy’s plant in Alberta is supported by CAN$8m in funding from Emissions Reduction Alberta’s (ERA) Industrial Efficiency Challenge, with the new facility expected to be commissioned toward the end of 2022.

Other commercial opportunities

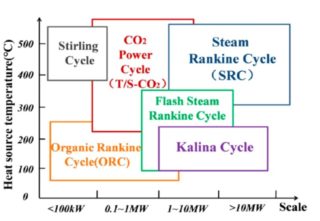

Work by other researchers such as Liuchen Liu and colleagues at the University of Shanghai for Science and Technology, Shanghai, China (see paper Liu et al, 2020) shows that sCO2-based cycles are particularly suited to waste heat recovery applications, both in terms of the heat source temperature and typical power output size, as can be seen in the diagram below.

![]()

sCO2 cycle compared with other thermodynamic cycles (source Liu et al, 2020)

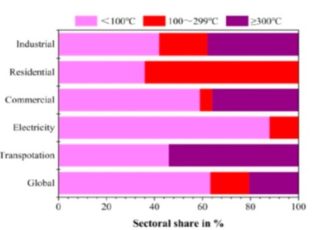

They also show that low-temperature (typically <350°C) waste heat accounts for the majority in most end-use energy sectors. As shown below, there is a range of energy-from-waste opportunities across industrial, residential, commercial, electricity and transport sectors. Around 63% of the waste heat streams is actually at temperatures below 100°C.

![]()

Sectoral shares of waste heat distribution on a global basis (source Liu et al, 2020)

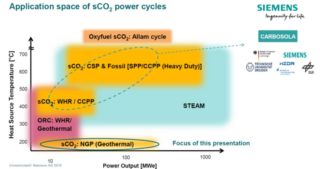

Indeed, Siemens Energy has been working in Europe on sCO2 for the last few years with a range of potential applications in mind. They have done much of the preparatory work as part of the Carbsola research project with €2.2m of funding from the German Ministry of Economic Affairs and Energy. Together with Dresden University of Technology, the Helmholtz Centre in Dresden and the German Aerospace Centre in Cologne, they have been working to show that the technology for sizeable volumes of waste heat is commercially mature. In addition to using the waste heat from gas turbine combined cycle power plants (CCPP), the research partners are testing its use in concentrated solar power (CSP) plants and Siemens have also shown the potential application of the technology for waste-heat recovery in geothermal applications (so-called Next Generation Geothermal Power – NGP), as shown in the figure below.

![]()

Potential applications of sCO2 technology (source: Siemens AG)