-

Hydrogen and combustion: big challenge, big chance

Date posted:

-

-

-

Post Author

Philip SharmanIFRF Director

-

-

Since October, exploring the fascinating, many-faceted topic of hydrogen energy, this series of blogposts has ventured far and wide across some intriguing terrain. Questions about hydrogen production in a world that is, perhaps, finally starting to set its ‘energy satnav’ for a zero-carbon future; the diverse, dizzying array of ways that hydrogen energy could potentially be harnessed; the critical issue of how to secure public trust in the whole concept of hydrogen energy; how the benefits stack up against those of other promising energy vectors such as ammonia – any substantive change in the way we meet our energy needs has many dimensions, but hydrogen arguably has more than most.

But I haven’t yet tackled the biggest issue of all: the need to turn this promising component of clean energy systems into useful ‘work’ (in the physics sense) – in other words, usable electricity and/or heat – ever more efficiently and cost-effectively, consistent with an increasingly urgent environmental agenda. Unless this can be achieved, every other question fades into irrelevance.

For the combustion community, the challenge translates into a timely, potentially huge opportunity. A flourishing, mutually beneficial long-term relationship between hydrogen energy and combustion technologies has real scope to develop. More specifically, combustion can play a massive part in enabling hydrogen to emerge as a compelling energy option – giving combustion a welcome chance, in turn, to reinvent and reposition itself as a green technology with a very bright future.

Defining Issues

Let’s start with the most fundamental question of all: what is combustion? Only a wide definition adequately covers all the opportunities for combustion technologies to drive hydrogen energy forward.

To my mind (and hopefully yours!), combustion isn’t just a matter of ‘burning something’ to turn its energy content into heat and/or light. It’s a chemical process where a substance combines with an oxidising agent to produce heat, and this includes any complete or partial oxidation process which is exothermic. Viewed this way, fuel cells are a combustion technology: although the hydrogen fuel doesn’t burn, it reacts with oxygen that strips electrons from the gas to produce an electrical current. And fuel cells also happen to be a technology where plenty of scope still exists both for incremental improvements that accelerate wider take-up and, perhaps, for bigger leaps forward too.

It would be crazy to claim that fuel-cell technology (a term embracing a whole catalogue of different families of chemistries and design concepts) hasn’t made big advances in development, demonstration and deployment. But being old enough to vividly recall when this ‘new kid on the block’ first started making people sit up and take notice 30 years ago, it has perhaps failed to realise all the strides I might have hoped for if I’d predicted fuel cells’ future back then.

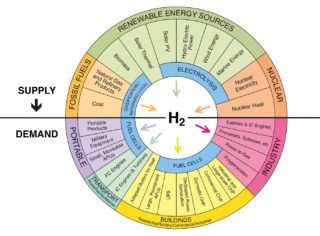

Maybe fuel cells’ diversity (in terms of their various types) and versatility (in terms of their numerous applications) are part of the problem. As the diagram shows, there are endless ways of harnessing the technology. Transport applications, for instance, offer many opportunities – cars, trucks, buses, trains, planes, boats, camper-vans: the list goes on and on. Nor does fuel cells’ appeal due to their mobility end there: in a host of portable applications in civil and military contexts, they could touch (and in many cases are already starting to touch) everything we do. And that’s before you consider their potential impact as a primary, back-up or uninterruptible power supply in stationary electricity generation or CHP and micro-CHP applications in commercial, industrial and residential settings.

Hydrogen – primary sources, conversion, applications and sectors (©Evenlode Associates Ltd – used with permission)

The fact is, there’s still plenty to do before we arrive at the best possible fuel cell options for every type and every scale of application – and the combustion community can have a big say in delivering them. Fuel cells are far from the ‘finished article’ and undoubtedly warrant further attention to drive costs down and efficiency and durability up. Imagination and fresh insight can still ensure deployment more quickly and widely than their current trajectory might suggest.

Burning Ambitions

It’s always tempting to focus on possibilities presented by ‘new’ technologies such as fuel cells. But hydrogen also has much to offer in making inroads into more traditional areas – including core areas of combustion revolving around the tried, tested practice of ‘burning something’…

Indeed, providing a platform to help hydrogen supersede fossil fuel combustion, in whole or part, could become a defining mission for the combustion community in the 21st century. Again, as the diagram shows, the diversity and sheer extent of the possibilities are striking, in transport, buildings and industry. Harnessing hydrogen in internal combustion engines adapted to run on hydrogen or fuel mixes with hydrogen content; ensuring turbines can run on gas mixed with increasing levels of hydrogen; developing specially adapted hydrogen-fired boilers to meet residential or commercial space- and water-heating needs – combustion technologies have a pivotal role to play in making it all possible. ‘Power-to-gas’ (P2G) and methanation (i.e. reacting hydrogen with CO2 to form energy-rich methane) are other promising areas where increasingly efficient, cost-attractive combustion technologies could make a vital difference to deployability. And it’s the same story with ‘polygeneration’, whether that involves delivering heating, cooling and electricity, or more complex concepts producing a broader ‘slate’ of products such as chemicals, materials or fuels – with the right combustion technologies for the right applications crucial to making it happen.

But let’s conclude by looking unashamedly at the most ‘traditional’ combustion market of all – and one that must urgently adjust and adapt to a future where being green will surely be increasingly non-negotiable. From process heat to space-heating and hot water, industry’s need for heat is undiminished. Indeed, industrial heat accounts for nearly a fifth of global energy use, with demand for high-temperature heat in sectors like iron and steel, cement, glass, ceramics, metal finishing and others accounting for over half of industrial heat requirements worldwide. The imperative is to meet such demand more cleanly and, as an especially promising option for meeting heat requirements over 1000°C, hydrogen could be a big part of the answer. That means pinpointing innovative, optimised, modular, scalable combustion options – not just ‘whole technologies’ but also their individual components – that can meet technical specifications cost-effectively while staying in step with the green agenda.

Naturally, barriers and hurdles will have to be confronted. But if hydrogen is to be part of the solution to the fast-looming climate crisis – and, as this series has shown, there’s a real case to be made that it could and should – the combustion community holds the key to unlocking the door to a stimulating, surprising, rewarding energy future where hydrogen finds itself holding many of the cards.