-

Hybrit sells first fossil fuel-free steel to Volvo Group in Sweden

Date posted:

-

-

-

Post Author

Greg Kelsall

-

-

![]()

Swedish firm Hybrit has sold the world’s first steel that has been manufactured entirely without the use of fossil fuels. According to McKinsey, the steel industry accounts for around 8% of global greenhouse gas emissions, so a carbon-free product could go a long way to helping nations reach net-zero carbon by 2050.

Hybrit says its “carbon-free” steel is produced using hydrogen made via water electrolysis using renewable electricity instead of the coal and coke as used in the traditional process. The first sale of this ‘green’ steel was to the Volvo Group, which said in April that it would start production this year of prototype vehicles and components made using the steel. While it has started with small orders thus far, Hybrit says its goal is to deliver green steel to the market and demonstrate the technology on an industrial scale as early as 2026. It says that its technology alone has the potential to reduce Sweden’s total carbon dioxide emissions by approximately 10% and Finland’s by approximately 7%.

“The first fossil-free steel in the world is not only a breakthrough for SSAB, it represents proof that it’s possible to make the transition and significantly reduce the global carbon footprint of the steel industry. We hope that this will inspire others to also want to speed up the green transition,” said Martin Lindqvist, CEO of Swedish steel producers SSAB.

By way of background, the steel industry uses two main production processes for steel:

Blast furnace to basic oxygen furnace: The blast furnace to basic oxygen furnace (BF-BOF) process accounts for about 95% of the world’s virgin steel and some 70% of total steel production. It is a process in which iron ore is reduced and melted at temperatures around 1200°C. Coke, coal and/or natural gas are used as reducing agents. The resulting pig iron is then reacted with oxygen in a basic oxygen furnace (converter) to remove excess carbon content from the iron and to generate liquid steel.

Electric arc furnace: This process is used to produce recycled steel and the remaining fraction of virgin steel. In this case, electric arc furnaces (EAF) are either fed with scrap steel to make recycled steel or fed with direct-reduced iron (DRI) to produce virgin steel. Syngas produced from coal or natural gas is usually used as the reducing agent to reduce iron ore at temperatures below the melting point of steel. Recycled steel produced in an EAF tends to be of lower quality than virgin steel because it retains the contaminants that were present in the scrap steel, such as copper. The EAF and DRI-EAF processes have much lower CO2 emissions per produced tonne of steel than the coal-based BF-BOF production route.

DNV GL has noted that there are a number of options to decarbonise steel production:

- Applying carbon capture, utilisation and storage (CCUS) at the existing BF-BOF production sites

- Using biomass-derived charcoal instead of coal as a feedstock and fuel in BF-BOF production

- Using biogas or hydrogen instead of natural gas as a reductant in DRI production

- HIsarna, a DRI process for converting iron ore almost directly into liquid iron or hot metal, described previously in an IFRF blogpost. Indeed, IFRF carried out some of the initial development and testing of the cyclone converter for HIsarna with Hoogovens between 1989-1995 when located in IJmuiden

- Using low-carbon electricity in an EAF.

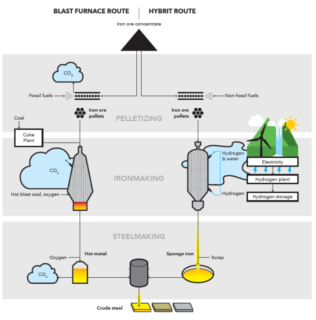

Hybrit’s technology (developed through the HYBRIT – HYdrogen BReakthrough Ironmaking Technology – Project, a collaboration between SSAB, mining company LKAB and utility company Vattenfall that started in 2017, and now marketed by Hybrit Development AB) therefore falls in to this last category of decarbonising steel production. The production route is similar to existing DRI processes, except that the hydrogen reacts with iron oxides to form water instead of CO2. Hybrit’s proposed DRI process is compared graphically with the traditional BF-BOF process in the figure below, with a more complete description provided by the Stokholm Energy Institute.

![]()

Comparison of BF-BOF and Hybrit steel manufacturing processes

To ensure that the electricity used is fully renewable, such projects would require sufficient hydrogen storage capacity to balance the hydrogen demand for the DRI process and the hydrogen supply from intermittent renewable power generation. Otherwise, the grid electricity used would have the carbon intensity of the local electricity generating mix, typically fossil fuel dominated in regions of high steel production such as China and the USA.