-

Breakthrough in selective chemical looping combustion could pave the way to cleaner, more efficient industry

Date posted:

-

-

-

Post Author

Greg Kelsall

-

-

In what is described as a breakthrough in selective combustion, researchers at the University of Minnesota Twin Cities in the USA have developed a new method to selectively burn a specific molecule in a mixture of hydrocarbons. Traditionally, eliminating small concentrations of contaminants is very challenging and energy-intensive, but this new method could provide a more energy-efficient alternative. This could make industrial processes more efficient and help remove pollutants. It has potential applications in industries such as fuel production, pharmaceuticals, fertilisers and plastics.

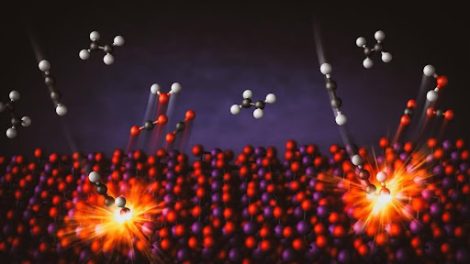

The paper entitled ‘Selective chemical looping combustion of acetylene in ethylene-rich streams’ by Jacobs et al, was published recently in Science, with a free to access overview provided in SciTechDaily. The editor’s note for the article in Science explains that trace acetylene can be removed from ethylene feedstocks by selective combustion of acetylene. The study found that the lattice oxygen of bismuth oxide (Bi2O3) can combust acetylene with more than 99% selectivity for gas streams containing equimolar or dilute amounts acetylene in ethylene. Lattice oxygen removed by combustion could be regenerated over many cycles by reaction with molecular oxygen. This alternative purification route to semi-hydrogenation of acetylene does not require elevated pressures and is tolerant to carbon dioxide and water impurities.

The study demonstrates how a bismuth oxide catalyst, a substance that speeds up chemical reactions, can be used to target and burn just one type of molecule in a mixture. The researchers successfully combusted small amounts of acetylene in the presence of ethylene. This is a key step in preventing catalyst poisoning during polyethylene production, an important part of the plastics industry producing over 120 Mtonnes of polyethylene each year.

“No one else has shown that you could combust one hydrocarbon present in low concentrations, in mixtures with others,” said Aditya Bhan, a Distinguished McKnight University Professor in the Department of Chemical Engineering and Materials Science and lead investigator on the paper.

The process is based on chemical looping to provide the oxygen. Conventionally, combustion processes burn all the hydrocarbon components in a fuel mixture at high temperature to produce heat. The use of a catalyst allowed the researchers to tackle the challenge of burning one molecule but not the others. The bismuth oxide catalyst is unique as it provides its own oxygen during combustion, rather than using oxygen from an outside source using the chemical looping concept.

The work was funded by the US Department of Energy, Office of Basic Energy Sciences. The work was completed in collaboration with the University of Minnesota Characterisation Facility and the Minnesota Supercomputing Institute.