-

What is black liquor?

Date posted:

-

-

Post Author

dev@edge.studio

1. Black liquor – A unique fuel

[GLOSS]Black liquor[/GLOSS] is the general name of the spent liquor from several alternative alkaline, neutral or acidic [GLOSS]wood[/GLOSS] pulping processes at elevated temperatures and pressures.

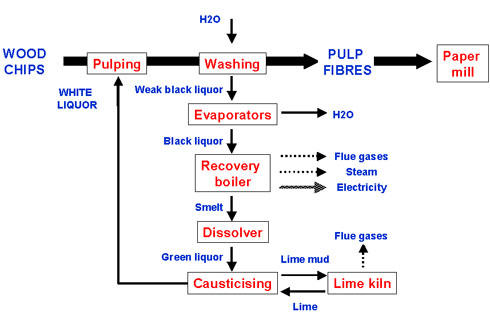

The dominant process is the strongly alkaline [GLOSS]kraft process[/GLOSS] using NaOH and Na2S as active [GLOSS]pulping chemicals[/GLOSS]. See Figure 1 in which the chemical recovery cycle is shown diagrammatically.

Figure 1: Chemical recovery cycle

The initial concentration of weak black liquor from the pulping process is about 15% [GLOSS]dry solids[/GLOSS] in water. It is concentrated to firing conditions between 65% and 85% dry solids content in an evaporator unit.

At this stage it is a dark, viscous and strongly sulfurous smelling liquid, which contains the inorganic pulping chemicals (~50% of dry solids) along with [GLOSS]lignin[/GLOSS] and other organic matter (~50% of dry solids) separated from between the wood fibres during pulping in the digester.

Black liquor is fired in a recovery boiler for two reasons:

· On one hand, the liquor releases heat as it burns and this is used for production of steam and power. In this sense black liquor can be classified as an industrial [GLOSS]fuel[/GLOSS], effectively a [GLOSS]biofuel[/GLOSS].

· On the other hand, pulping chemicals in the liquor are recovered during the combustion process for reuse in the cooking process.

Despite being a liquid, thermal conversion of black liquor shows [GLOSS]combustion[/GLOSS] characteristics like that of solid fuels, rather than those of [GLOSS]petroleum[/GLOSS] derived liquid fuels.

Rather than evaporating and burning in the gas phase like a typical liquid fuel droplet, black liquor conversion starts with evaporation of water from the droplet and continues with the same stages of combustion as a solid fuel, such as coal.

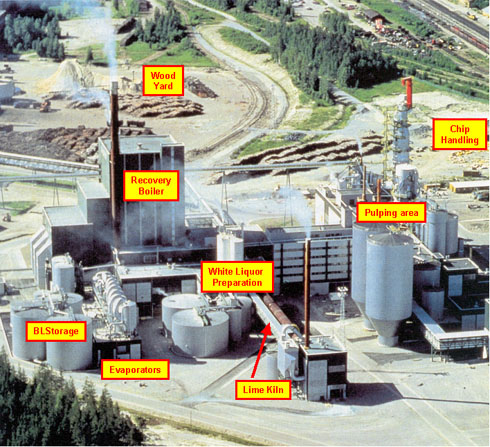

The heating value of typical black liquor is around 15 MJ/kg dry solids. The amount of heat released during thermal conversion of black liquor in large units called black liquor recovery boilers is not trivial since it is an energy production unit and a unit for producing inorganic chemicals. Because of this, it contributes significantly to the overall energy production in the Nordic countries and North America and accumulates e.g. for Finland up to 9% of the non-nuclear energy production. A typical unit is shown in Figure 2 below.

Figure 2: A pulping facility with recovery boiler and ancillary equipment

2. Characteristics of black liquor

Black liquor is a complex mixture of water, inorganic salts and organic matter. Table 1 shows elemental composition and species composition of typical kraft black liquor.

|

Chemical Species in kraft black liquor (% of dry solids) |

Elemental composition of kraft black liquor (% of dry solids) |

||

|

Alkali lignin |

30-45% |

Carbon |

34-39% |

|

Hydroxy acids |

25-35% |

Hydrogen |

3-5% |

|

Extractives |

3-5% |

Oxygen |

33-38% |

|

Acetic acid |

5% |

Sodium |

17-25% |

|

Formic acid |

3% |

Sulfur |

3-7% |

|

Methanol |

1% |

Potassium |

0.1-2% |

|

Sulfur |

3-5% |

Chloride |

0.2-2% |

|

Sodium |

15-20% |

Nitrogen |

0.04-0.2% |

|

|

|

Others |

0.1-0.3% |

Table 1. Chemical species and elemental composition of kraft black liquor from North American wood species.

Each of these components plays an important role in determining the chemical conversion characteristics and material properties of black liquor.

Part of the problem with deriving general correlations for liquor composition and properties is the very broad range of pulping conditions encountered in practice. The pulping conditions influence both the relative amounts of the components in black liquor and thereby it’s properties.

Some black liquor properties, such as [GLOSS]calorific value[/GLOSS], heat capacity and density, depend on the nominal composition of the black liquor solids. These properties differ from mill to mill, but they are related directly to wood species, pulp yield and [GLOSS]Kappa number[/GLOSS].

Others, such as [GLOSS]viscosity[/GLOSS], depend on the process conditions in chemical pulping and cannot be predicted as easily (Table 2).

|

|

Dry solids [%] |

Temp. [°C] |

Boiling point rise [°C] |

Liquor viscosity [m Pa s] |

Heat capacity [J/kg °C] |

Density [kg/m3] |

|

Weak liquor |

15 |

77 |

1.4 |

0.7 |

3870 |

1070 |

|

Liquor in evaps. |

18 |

57 |

1.7 |

1.1 |

3790 |

1100 |

|

Liquor in evaps. |

21 |

74 |

1.9 |

0.9 |

3740 |

1110 |

|

Liquor in evaps. |

26 |

87 |

2.8 |

0.9 |

3660 |

1130 |

|

Liquor in evaps. |

35 |

132 |

4.2 |

0.8 |

3560 |

1150 |

|

Liquor in evaps. |

50 |

104 |

8.1 |

5.0 |

3230 |

1270 |

|

Strong liquor |

65 |

104 |

13.9 |

63 |

2960 |

1360 |

|

Strong liquor (as fired) |

65 |

118 |

13.9 |

34 |

2960 |

1350 |

|

High solids liquor |

80 |

182 |

26.7 |

48 |

2670 |

1390 |

|

High solids liquor (as fired) |

80 |

146 |

26.7 |

253 |

2670 |

1440 |

Table 2. Typical property values at various stages of black liquor evaporation and firing.

3. Black Liquor – relationship with industrial fuels

Industrial fuels are introduced in CF62.

In the present CF Black Liquor is shown to be a liquid bio-fuel with a significant input to the overall primary fuel supply, especially in the northern countries, e.g. Canada, the Nordic Countries, the Russian Federation; some northern states of the USA and so forth.

However despite the fact that it is a liquid fuel, the combustion characteristics and burning behaviour differ markedly from its counterpart petroleum derived liquid fuels, as described in CF186 and CF223.

The properties and combustion characteristics of black liquor are described in Related Combustion Files CF57, CF200, CF201 and CF202.

Sources

[1] Authors

[2] Adams, T.N. (Ed.), Kraft Recovery Boilers, Tappi Press, Atlanta, 1997.