-

Cool Planet Technologies demonstrates breakthrough success in carbon capture membrane module testing

Date posted:

-

-

Post Author

Tracey Biller

-

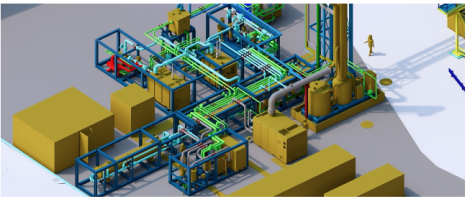

Cool Planet Technologies has successfully tested its third-generation carbon capture membrane module, validating the scalability and performance of the proprietary process at flow rates of up to 37,000 tonnes per annum (tpa) of CO2 captured and recovery rates of 95% CO2. This was achieved under a range of conditions designed to represent industrial emissions from a wide range of sectors, including lime, cement, steel and waste-to-energy.

The company says demonstrating performance at scale removes one of the most significant risks for large-scale capture and indicates its capability to deliver industrial-scale solutions. Moreover, the module’s measured performance very closely matched its simulation model, confirming the accuracy of Cool Planet’s predictive tools for designing large-scale plants.

Valuable insights gained during testing will be incorporated into the next generation of high-performance capture modules currently being developed.

To showcase this achievement, Cool Planet hosted a series of demonstration days at its Grimsby facility in the UK. Over 20 leading companies from industries including the lime, cement, steel and waste-to- energy sectors attended live demonstrations of the carbon capture process. Further specific tests were also conducted with a lime manufacturer in support of a specific project which will use Cool Planet’s technology to decarbonise one of their European lime kilns.

The module will now be integrated into the demonstration project at Holcim’s Höver cement plant in Germany. This project will initially operate for twelve months, serving as a full-scale validation for Cool Planet’s carbon capture technology and advancing the technology to TRL8.