-

What is convective heat transfer?

Date posted:

-

-

Post Author

dev@edge.studio

1. What is Convective Heat Transfer?

Convective heat transfer occurs between a moving fluid and a solid surface or to another point in the fluid. In thermal plant design, convection to or from a surface is normally the main concern.

Convection also embraces the mechanism of molecular conduction occurring in fluids. This fluid motion can be induced by either density / temperature differences in the fluid – so called free or natural convection – or by external transfer of momentum to the fluid which is termed forced convection.

2. What is a Convective Heat Transfer Coefficient

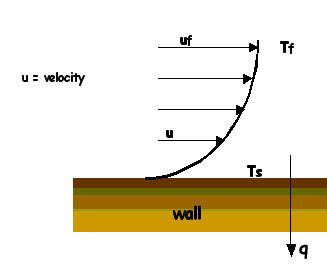

The convective heat transfer between the fluid and the surface occurs across a thermal boundary layer through which the temperature of the fluid changes and, in theory, the heat exchange can be defined by calculation of conduction at the surface. However, the precise determination of the necessary temperature gradient in the fluid at the surface is very difficult and it is more convenient to express the heat transfer in terms of an overall temperature difference.

Thus, the rate of convective heat transfer between the surface at a temperature Ts and the fluid at Tf is given by Newton’s Law of Cooling, written as:

q = h (Tf –Ts )

Where:

q is the heat flux (W/m2)

h is the [GLOSS]convective heat transfer coefficient[/GLOSS], sometimes referred to as the film heat transfer coefficient (W/m2K)

T is the temperature (K)

h is dependent on a number of factors:

– fluid velocity profile

– [GLOSS]turbulence[/GLOSS]

– fluid properties and temperature

– temperature difference across the boundary layer

– upstream thermal and hydrodynamic conditions

Therefore, h and q will often vary with position.

|

Conditions |

Convective Heat Transfer Coefficient W/m2K |

|

Natural convection from a 5cm diameter horizontal tube in air with ∆T = 30 °C |

6.5 |

|

Natural convection from a 2cm diameter horizontal tube in water with ∆T = 30 °C |

890 |

|

Air with a velocity of 2 m/s passing over a 0.2m square plate |

12 |

|

Air with a velocity of 6 m/s passing over a 10 cm diameter tube |

31 |

|

Air with a velocity of 17.5 m/s flowing in a 10cm diameter tube |

45.5 |

|

Water at 0.5 kg/s flowing in a 2.5cm tube |

3500 |

Table 1: Typical values of convective heat transfer coefficient h showing how h varies with fluid properties and system geometry (for illustrative purposes only)

It is possible to predict the heat transfer for flow over surfaces but this is can be very difficult and requires very high levels of accuracy. It is customary, therefore, in all but the simplest cases to use empirical equations to obtain h and these are often expressed in the form of non-dimensional numbers such as the [GLOSS]Nusselt number[/GLOSS], [GLOSS]Reynolds Number[/GLOSS] and [GLOSS]Prandtl Number[/GLOSS] for forced convection and the [GLOSS]Grashof Number[/GLOSS] and [GLOSS]Rayleigh Number[/GLOSS]for free convection.

3. Why is Convective Heat Transfer Important in Heating Plant Design?

Convective heat transfer can be a significant proportion of the heat transfer between the hot combustion products and the surfaces in certain types of industrial heating plant, particularly when fired with gaseous fuels producing [GLOSS]non-luminous flames[/GLOSS]. For example in the [GLOSS]firetube[/GLOSS] (1st pass) of a natural gas-fired [GLOSS]shell boiler[/GLOSS] around 40% of the heat transferred from the flame will be by convective heat transfer. Likewise, in a [GLOSS]watertube boiler[/GLOSS] a large proportion of the heat transfer in the [GLOSS]superheater[/GLOSS] and [GLOSS]ecomoniser[/GLOSS] sections will be via convection. Moreover, some designs of metal reheating furnaces are specifically designed to promote high rates of convective heat transfer by, for example, directing a high-velocity jet of combustion products to impinge onto the stock.

Natural convection is important in calculating the heat losses from the external surfaces of plant and both single-phase and two-phase convection need to be quantified for process fluid heat transfer, for example boiling and condensation.

Sources

[1] North American Manufacturing Company, Combustion Handbook, Volume 1, Third Edition, 2001

[2] J M Rhine and R J Tucker, Modelling of Gas Fired Furnaces and Boilers, McGraw-Hill Book Company, 1991 ISBN 0077073053