-

What is a dust explosion

Date posted:

-

-

Post Author

espadmin

1. What is an explosion?

Definition

Before the phenomenon of a dust explosion is described, a definition of an explosion is required. An explosion is sometimes referred to as: devastating, a (very) rapid fire, a bang etc. In literature there exists many definitions for an explosion. In this text, the following definition is used:

An explosion is a sudden, violent release of energy accompanied by the build-up of pressure waves (blast). This definition focuses both on the cause, namely the release of chemical or mechanical energy, and on the effect. This can be the noise or “bang” due to the sudden release of a strong pressure wave or a blast wave.

Fire triangle

In order to have a fire or a release of chemical energy the three components of the fire or combustion triangle (CF173) are necessary. These are a fuel, an oxidant and an ignition source. These three elements are needed in order to have an exothermal oxidation reaction or combustion. These three elements are necessary but not always sufficient to have a combustion or explosion. For example, a mixture of the fuel and the oxidant is only flammable if the fuel concentration lies between the flammability limits, i.e. the lower and the upper flammability limit of the fuel. The ignition source has also to be stronger than the minimum ignition energy of the fuel/oxidant mixture. It can be seen that the fire triangle already gives information about the causation and the prevention of an explosion.

2. What is a dust explosion

Dust

For a dust explosion the fuel of the fire triangle can be any solid material that can burn in air. If the particle size of the solid is fine enough, the violence or speed of combustion will increase. If a solid is cut into small particles the total contact surface area between the dust and air will increase and an explosion can occur instead of a slow combustion. The combustible dust can include all kind of materials [1], such as natural organic materials (grain, sugar, etc.), synthetic organic materials (plastics, organic pigments, pesticides, etc.), coal and peat and metals (aluminium, magnesium, zinc, iron, etc.).

Dust explosion pentagon

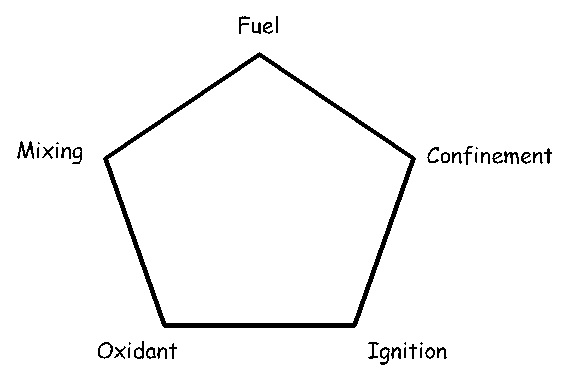

In the dust explosion pentagon two additional components are added to the three components of the fire triangle, namely the mixing and the confinement, see Figure 1 [2]. The dust must be well mixed or suspended in the air. This is a main difference with a gas mixture, where the homogeneity is much more evident, while the dust/air mixture is strongly influenced by gravity. A last component of the explosion pentagon is the confinement. When a dust/air mixture burns in the open air, a deflagration, without pressure build-up is obtained. In order to create a dust explosion a confinement is needed. This can be the volume of a process apparatus or the building in which dust layers are formed. This confinement can also be formed by obstructions, such as tubing or installations which can cause pressure build-up.

Figure 1: The dust explosion Pentagon

As in the fire triangle, the dust concentration must be large enough or higher than the lower explosion limit in order to obtain a flammable dust mixture. The upper explosion limit is less relevant for dust mixtures since the dust is influenced by gravity and even for high concentrations of dust, places can always be found that are still within the flammability limits. After particle size, the moisture content is also an important parameter that influences the dust explosion properties of a dust mixture.

3. Dust explosion characteristics

The dust explosion characteristics describe the “explosivity” of a product. These properties can be subdivided in two categories.

The first category is the explosion sensitivity characteristics, such as the [GLOSS]lower explosion limit[/GLOSS], the minimum ignition energy, minimum cloud ignition temperature, minimum layer ignition temperature, limiting oxygen concentration, etc. In order to assess the explosion risk these parameters are needed.

The other category is the explosion severity characteristics, such as the maximum explosion pressure, the maximum rate of pressure rise or the [GLOSS]KSt-value[/GLOSS]. These parameters describe the effect of the dust explosion.

These parameters can be determined in standardised test apparatuses according to international standards. More information about these tests can be found in [3]. It is important to remember that these tests are performed at standard conditions (ambient temperature and pressure) which sometimes differ from real industrial process conditions (elevated temperature, pressure, high volumes). These differences must be taken into account when assessing the explosion risk.

Sources

[1] Eckhoff R.K., Dust Explosions in the Process Industries, 3rd edition, Gulf Publishing Elsevier, Boston, United States, ISBN-10: 0750676027, 2003.

[2] Amyotte P., 2013, An Introduction to Dust Explosions. Understanding the Myths and Realities of Dust Explosions for a Safer Workplace. Butterworth-Heinemann, Oxford, UK, 2013.

[3] http://www.adinex.be/en/dust-explosions.htm

Acknowledgements

The research leading to these results has received funding from the European Community’s Seventh Framework Programme (FP7/2007-2013) under grant agreement n° 268191.