-

What factors influence burner stability when combusting Works By-product Gases (Low-CV Fuels)?

Date posted:

-

-

Post Author

dev@edge.studio

1. Background

Flame stability is an important factor for the design and operation of all burners. Guidance for the design of stable natural gas flames is given in CFs 2, 3 and 5. The combustion of low [GLOSS]calorific value[/GLOSS] (low-CV) gases, such as [GLOSS]Works By-Product Gases[/GLOSS] ([GLOSS]WBPG[/GLOSS]) (CF100) found in the iron and steel industry, can present special problems. These difficulties stem from the composition of the fuel, which often varies with time, and the design of the burner. In many cases the problems arise from a combination of these factors.

The test programme for IFRF G2 trials [1] was aimed at quantifying the impact fuel composition and burner design parameters have on burner stability and operation for WBPG gases. This Combustion File summarises the G2 trial findings and can be used as an indication of assessing burner stability criteria for low-CV fuels.

Five burner designs were tested:

Simple concentric tube arrangement

Scaled-down version of G1 trial burner [2]

RIT (Swedish) development burner with variable air and fuel flows

Hoogovens (Corus) design lean gas burner with central fuel injection

IFRF designed twin-air burner with gas injection between the air nozzles

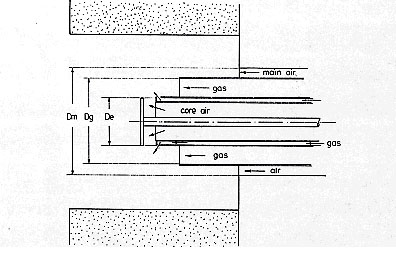

(Figure 1)

(Note: A water-cooled housing was used for all burners except the IFRF twin-air burner)

Figure 1. The IFRF twin-air burner used in G2 Trial

2. Factors Influencing Flame Stability

Fuel Composition Factors

Fuel composition has the largest influence on flame stability, especially its H2 content.

Generally for a low [GLOSS]flame speed[/GLOSS] and low CV fuels, flame stability can be improved by:

· Mixing the fuel with a high-CV, gas such as [GLOSS]COG[/GLOSS] ([GLOSS]Coke Oven Gas[/GLOSS]) or [GLOSS]Natural Gas[/GLOSS] (NG)

· [GLOSS]Oxygen enrichment[/GLOSS](CF 61)

· Air preheat

· Using a ceramic burner head with premixed fuel and air

However, operational and economic factors will impact on these options. Air preheat is the most common option and improves stability by increased flame speed and by better mixing resulting from the higher velocities. CO enrichment of the fuel has little influence on flame stability. Ceramic burner components are unsuitable for gases containing significant concentrations of H2, because of light-back problems.

The G2 trials identified the importance of ignition energy, whereby a minimum energy must be available around the recirculation zone to guarantee ignition of the surrounding flow.

For a lean, low-CV, fuel with changing properties flame, stability will be influenced by:

· Flame speed: the flame may become unstable if the flame speed becomes too low and/or the local gas/air mixture goes outside the [GLOSS]flammability limits[/GLOSS]

· If the flame speed varies and decreases below a critical value, then even stabilisation within a burner [GLOSS]quarl[/GLOSS] becomes impossible

· The quantity of H2 in the low-CV fuel has a strong influence on burner stability. For example for the twin-air burner used in the G2 trials, it was stable above 3% H2 concentration for a gas with a CV as low as 3.6 MJ/m3.

· For low-CV fuels with high H2 contents it is possible to change the gas velocities without the risk of blow-off

Generally the influence of fuel composition on the limits of stability for particular designs of burners will need to be established experimentally.

Burner Design Factors

When considering the design of the burner for low-CV fuels, the gas velocity has the largest influence on flame stability: air velocity has less of an impact.

Changing cross sectional flow areas to maintain velocities when increasing air preheat, reduces these stability benefits

Based on the fuels tested in the G2 trials (see table below), it can be concluded that:

· Problems with flame stability originating from changes in burner exit velocities, in order to maintain a constant thermal input, will be more severe with these low-CV fuels. The situation is compounded during turndown when the burner aerodynamics can considerably change.

· Using a divergent quarl, which promotes a strong internal recirculation zone, gives shorter flames that are stable over a wider range of input parameter. However, the stability remains a function of burner size, especially for very low-CV gases, such as [GLOSS]Blast Furnace Gas[/GLOSS] ([GLOSS]BFG[/GLOSS]), and when constant velocity scaling is applied, because of the lower residence times.

· For burners with a central gas gun within the quarl, its position has a strong influence on flame shape and subsequent burner stability (CF3). The problems are particularly noticeable at the extremes of low-CV gas quality (gases with high and low-CVs)

· Of the four burners assessed, the IFRF twin-air design of burner gave the widest flexibility in that it can utilise the widest range of gas qualities and thermal inputs.

· Using a central air supply will sometimes produce a more intense flame giving improved performance but without influencing flame shape and length.

· For the burners with a central stabiliser, such as the IFRF twin-air burner, its position has a small effect on the performance and stability, provided that the central (core) air rate is kept constant (Figure 1).

3. Limitations of Stability Criteria

The G2 trials were undertaken on an IFRF test furnace with the following parameters:

· Furnace dimensions: 1.2m x 1.2m x 4.5m

· Heat input between 0.5 and 2.07 MWth: most ~1.0 MWth

· Maximum air preheat temperature 400 ºC

Fuel types tested and corresponding fuel properties are summarised in the table below:

Property |

BFG |

BOFG |

BFG/BOFG mix |

BFG/COG mix |

BFG/ NG mix |

|

LCV (MJ/m3) |

3.2 |

8.6 |

5.9 |

5.9 |

5.9 |

|

Air requirement I, mair (m3air/m3fuel) |

0.61 |

1.62 |

1.1 |

1.31 |

1.34 |

|

Air requirement II, mair (m3air/MJ |

0.19 |

0.19 |

0.19 |

0.22 |

0.23 |

|

[GLOSS]Wobbe Index/Number[/GLOSS] MJ/m3 |

3.1 |

8.4 |

5.8 |

6.2 |

5.9 |

|

[GLOSS]Weaver Index[/GLOSS] |

4.7 |

11.2 |

8.0 |

12.5 |

6.2 |

BFG – Blast Furnace Gas, BOFG – Basic Oxygen Furnace Gas, COG – Coke Oven Gas, NG – Natural Gas (88% CH4)

LCV – lower calorific value, m – volume flow rate at standard conditions

The Combustion File has summarised the conclusions of the G2 study, but great care is needed in extending the conclusions to other low CV gases, operating parameters and different burner arrangements. The study confirmed the importance of burner testing for quantifying the performance and stability window.

Sources

[1] Schreier, W.S. Study on the burner design characteristics required for the combustion of variable quality lean gases: Report on G2 trials, IFRF Doc No. F 084/a/1, December 1984.

[2] Michel, J.B. and Payne R. The use of blast furnace gas as a fuel in high temperature furnaces in the steel industry: IFRF Doc. No. F 01/a/100, March 1979.