-

What are the emissivity characteristics of coatings for in-furnace thermocouple measurements?

Date posted:

-

-

-

Post Author

Neil Fricker

-

1. Background to thermocouple coating

In many combustion applications, coatings are deliberately applied for surface protection or to increase surface emissivities. Examples include the coating of thermocouples.

This combustion file considers the [GLOSS]emissivity[/GLOSS] of materials used in this application.

2. Effect of coating on thermocouple emissivity

An important example of the use of coatings in combustion systems is the use of silica films to prevent catalytic reactions taking place on platinum-based thermocouples in flames. In addition to protecting the thermocouple, the coating alters the emissive properties of the thermocouple surface, and hence the relationship between the thermocouple temperature and that of its surroundings. When undertaking measurement of flame and combustion product temperatures using fine wire thermocouples, it is important to know the emissivity of the thermocouple. The thermocouple can lose heat to the cold surroundings by radiation and this can result in the thermocouple indicating a lower than actual gas temperature. If the emissivity is known, correction can be made to the observed temperature reading to arrive at the true local gas or flame temperature.

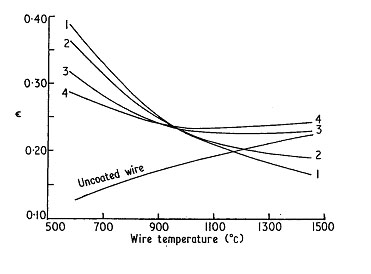

Figure 1 shows the variation of emissivity with temperature for the different thicknesses of coating. At the lower temperatures the coating produces a marked increase in [GLOSS]emittance[/GLOSS], but as the temperature increases this effect is reduced.

At the lowest temperature there is a continuing rise of emissivity with coating thickness and this is because an appreciable proportion of the radiant energy originates in the silica coating.

At higher temperatures, a different effect is observed. At higher temperatures [GLOSS]blackbody[/GLOSS] emission resides increasingly in the lower wavelength region where the silica is almost transparent. A very thin coating appears to have a higher emissivity owing to the transparency of the silica to radiation from the metal below. An increase in thickness eventually leads to a decreasing emittance as more of the radiation originates at the surface of the silica rather than from the metal surface at its core.

Fig. 1. Variation of total hemispherical emittance with temperature for different thicknesses of coating on a thermocouple. Assumed thermocouple diameter 12.7 mm; coatings 1, 53.3 mm; 2, 38.1 mm; 3, 22.9 mm; 4, 17.8 mm.

Sources

Hampartsoumian, E., Hainsworth, D., Taylor, J.M. and Williams, A. THE RADIANT EMISSIVITY OF SOME MATERIALS AT HIGH TEMPERATURES, Journal of the Institute of Energy, Volume 74, p91, 2001