-

What are the applications of Coke Oven Gas?

Date posted:

-

-

Post Author

dev@edge.studio

1. Introduction

The typical fuel gases used in integrated iron and steelworks are listed in CF62 and introduced in more detail in CF100. This group of industrial fuel gases includes [GLOSS]Coke Oven Gas[/GLOSS] or [GLOSS]COG[/GLOSS].

COG is produced as a by-product from [GLOSS]coke[/GLOSS] production. COG is valuable since it can be used as a relatively rich gaseous fuel in various applications inside or outside the steel plant.

The production of COG, its fuel gas properties, and its combustion and flue gas characteristics are described in associated Combustion File numbers 217, 239 and 240 respectively.

The present combustion file reports on the applications of Coke Oven Gas and related matters.

2. Storage and Distribution

In CF239, the production cleaning of raw COG is described.

The cleaned COG is ready to be used as a fuel gas for several applications. Therefore it must be stored and distributed. This is normally done via gasholders and pipelines.

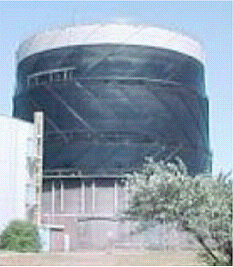

In Figure 1 the Coke Oven Gas holder on the site of Corus IJmuiden is shown.

A gasholder may contain up to 90,000 m3 of gas at a pressure up to 50 mbar. The gasholder acts to “smooth out” short-term differences in:

q Rate of supply from the coke plant and the rate of demand,

q Gas composition.

It also helps by providing a constant supply pressure for Coke Oven Gas compressors. The gas compressors elevate the pressure of the Coke Oven Gas up to 300 to 500 mbar for distribution via the pipelines.

Figure 1 Coke Oven Gas Holder – Corus IJmuiden

To transport the Coke Oven Gas from the gasholder to the consumers, a distribution net via pipelines (gas mains) is necessary.

Since Coke Oven Gas is normally saturated with water vapour, drip legs need to be installed in the pipeline system to remove water. This, together with the required maintenance of the pipelines (i.e. regular inspection, mechanical and chemical cleaning), makes the construction and operation of the distribution system relatively expensive.

3. Applications

Coke Oven Gas may be used directly as a fuel; for example in the combustion chambers of the [GLOSS]coke ovens[/GLOSS] (see CF217) in on-site process furnaces such as steel [GLOSS]reheating furnace[/GLOSS]s, and in power plant equipment such as boilers or gas turbines. One of the biggest consumers is the coke plant itself, where up to 50% is used as the coke plant fuel.

COG is also very suitable as so-called “make-up” fuel. In this case COG is mixed with another gas (e.g. [GLOSS]Blast Furnace Gas[/GLOSS]) to enhance and control the [GLOSS]calorific value[/GLOSS] (or [GLOSS]Wobbe Index/Number[/GLOSS]) of the gas mixture.

If the fuel gas is used in the stoves of [GLOSS]blast furnaces[/GLOSS], Coke Oven Gas may be added to the Blast Furnace Gas to enhance and control the [GLOSS]adiabatic flame temperature[/GLOSS].

4. Health and safety considerations

Coke Oven Gas is highly toxic since it contains significant amounts of carbon monoxide and light hydrocarbons and possibly trace elements such as benzene, ammonia, hydrogen cyanide and hydrogen sulphide.

Inhaling large amounts of COG directly causes dizziness followed by fainting, and eventually causes death.

Long term inhaling of small amounts of this gas might lead to cancer and is detrimental for the unborn child [8].

Finally, it must be recogised that COG is a highly explosive gas, with relatively wide [GLOSS]flammability limits[/GLOSS] – see CF240.

Sources

[1] American Iron and Steel Institute, www.steel.org.

[2]Wilson, H. Fuels and Combustion, Reheating Technical Course.

[3] N.V. Nederlandse Gasunie, Physical properties of natural gases, Groningen, Netherlands, 1980.

[4] Militzer, M.R., UEC Coal & Coke Laboratory, Coke Production for Blast Furnace Ironmaking.

[5] Valia, H.S. Coke production for blast furnace ironmaking, Ispat Inland Inc, American Iron and Steel Institute.

[6] Platts, M. The coke oven by-product plant, ThyssenKrupp EnCoke, American Iron and Steel Institute.

[7] Zabetakis, M.G., Flammability characteristics of combustible gases and vapors, Bulletin 627, Bureau of Mines, 1965.

[8] Informatie Chemische Stoffen, werkinstructiekaart oxygas, Corus, 2002.