-

What are shaft kilns for lime manufacture?

Date posted:

-

-

Post Author

dev@edge.studio

1. Background

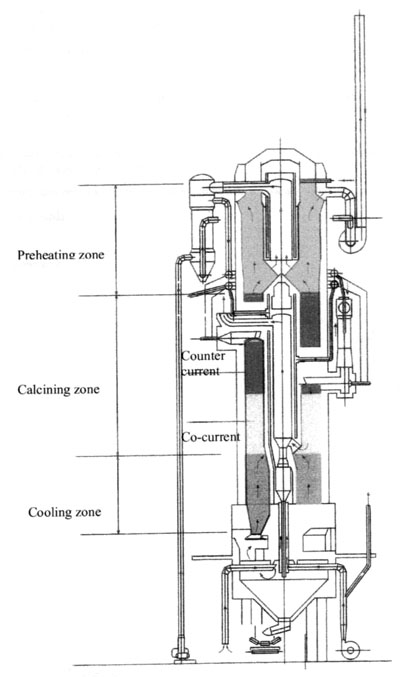

In a [GLOSS]shaft kiln[/GLOSS] there are three zones in which distinct operations involving heat transfer take place. They are:

· The preheating zone, in which the [GLOSS]limestone[/GLOSS] is dried and heated to [GLOSS]calcination[/GLOSS] temperature.

· The calcination zone, in which the stone dissociates.

· The cooling zone, in which the [GLOSS]quicklime[/GLOSS] is cooled.

The quality of the [GLOSS]lime[/GLOSS] is most influenced by the conditions in the calcination zone. Here, heat must be supplied at a temperature above the calcination temperature; which consequently results in a sufficiency of heat in the combustion gases and dissociated carbon dioxide to adequately heat the stone in the preheating zone. Unless the required product is a [GLOSS]hard burnt lime[/GLOSS], or [GLOSS]dead burnt lime[/GLOSS], the rate of heating in the calcination zone must be carefully controlled to ensure that there are no ‘hot spots’ or cool channels. Most of the design variations of shaft kilns are attempts to address this aspect of the kiln performance.

2. Types of shaft kilns

The available shaft kiln technologies fall into four types.

1. Single shaft

2. Double shaft (recuperative)

3. Annular

4. Inclined

The following pages give brief descriptions of typical kilns of each type, and a summary table of their operating characteristics is given at the end of this file.

3. Single Shaft Kilns

These are the most common forms of kiln in use. The vintage and number of manufacturers are large, but included in this list would be, in no particular order of preference; –

Mixed feed kilns

The mixed feed kiln is the most basic and oldest shaft kiln design, in which alternate layers of stone and fuel are laid on to the top of the preheating zone, and are then drawn down through the kiln as material is discharged at the bottom. Mixed feed kilns are still widely used in the ammonia soda process, and in regions of the world where the infrastructure and technical support are limited. The designs range from very basic small open top, hand loaded kilns relying on natural chimney draught to induce air through the bed, to large automatic feed and discharge, forced draft units. The latter are highly efficient, whereas the former are not.

A significant advantage of this type of kiln is that it can be operated to produce a consistently low [GLOSS]lime reactivity[/GLOSS]. Higher reactivity is usually only obtained at the expense of a higher level of residual CaCO3, which is not the case with more modern kiln designs. They are typically fired on a low volatile coal ([GLOSS]anthracite[/GLOSS]) or [GLOSS]metallurgical coke[/GLOSS], both of which have high ignition temperatures (~800oC). Higher volatile solid fuels, such as wood, tend to release the volatile components of the fuel in the preheating zone, which results in the excessive emission of smoke and a loss of some of the [GLOSS]calorific value[/GLOSS] of the fuel.

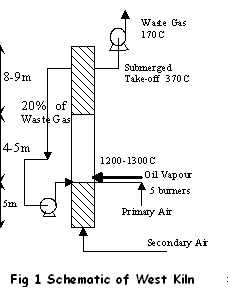

West kilns

These kilns are designed for two basic outputs, 50 and 100 tons/day lime, although more recent experience with these units has shown that they are capable of considerably increased output with suitable modification. They were originally designed for oil firing, using four, five or six ‘[GLOSS]carburetor[/GLOSS]s‘ equally spaced around the kiln at the base of the calcining zone, the idea being to [GLOSS]flash vaporize[/GLOSS] the oil on the hot walls of the carburetor chamber. This was achieved by injecting a solid rotating jet of oil which partially combusted with about 15% [GLOSS]stoichiometric[/GLOSS] air, before entering the burning zone, where it meets the cooling zone air and some recycled flue gas. An original schematic is shown in Fig 1. The original oil-firing concept was later abandoned for simple rotating oil injection onto the stone bed, and they have also been successfully operated using natural gas as the fuel.

These kilns are designed for two basic outputs, 50 and 100 tons/day lime, although more recent experience with these units has shown that they are capable of considerably increased output with suitable modification. They were originally designed for oil firing, using four, five or six ‘[GLOSS]carburetor[/GLOSS]s‘ equally spaced around the kiln at the base of the calcining zone, the idea being to [GLOSS]flash vaporize[/GLOSS] the oil on the hot walls of the carburetor chamber. This was achieved by injecting a solid rotating jet of oil which partially combusted with about 15% [GLOSS]stoichiometric[/GLOSS] air, before entering the burning zone, where it meets the cooling zone air and some recycled flue gas. An original schematic is shown in Fig 1. The original oil-firing concept was later abandoned for simple rotating oil injection onto the stone bed, and they have also been successfully operated using natural gas as the fuel.

Esjornsson

This kiln is of Swedish design in which the preheating zone is hexagonal, tapering into a rectangular burning zone of approximately 3.0m by 1.2m, and then opening out into a square cooling/discharge zone. A separate gasification unit is used to provide the heat to the calcining zone. Water sprays cool the gasified fuel before being injected into the calcining zone at two levels.

Fercalx (Union Carbide)

These kilns were originally designed by Union Carbide as mixed-feed, coke-fired units They were first converted in 1952 to gas or oil fired using water cooled [GLOSS]burner beam[/GLOSS]s at two levels and are now marketed by Fercalx. The ability to inject fuel at a large number of discrete points within the bed in the calcining zone enables a more even heat distribution to be achieved, although mechanical failure, distortion and the higher heat usage due to the beam cooling tend to outweigh this potential advantage.

Azbe

There are a large number of Azbe kilns in the USA, and other parts of the world, and there are a number of variations as the technology has developed. Typically, these kilns are of curved rectangular cross section, with a multiple level refractory burner beam for fuel, air and flue gases at the base of the burning zone on the longer kiln axis.

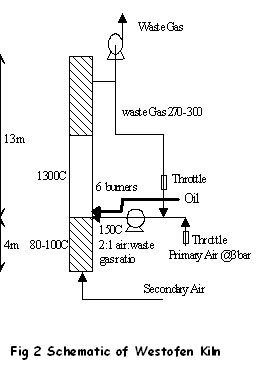

Westofen

This kiln design is similar to the West kiln using flue gas recycle and side firing at the base of the burning zone. Figure 2 shows a schematic of the design.

This kiln design is similar to the West kiln using flue gas recycle and side firing at the base of the burning zone. Figure 2 shows a schematic of the design.

SIC (Societa Impiante Calce srl)

SIC have two single shaft kiln designs, the CBK (central burner kiln) and the HPK (high performance kiln), the latter being designed for smaller stone.

Chisaki Koma

This kiln design of Japanese origin is based on fixed bed preheater technology as developed in the Davis preheater, or the Kraus-Maffai preheater.

4. Double Shaft Kilns

Double shaft kilns have been in use since the 1960’s, and were developed to overcome  the problems of increased bed resistance to gas flow with smaller sized stone. They employ the technique of regenerative flow, whereby two, or more, shafts are fired singly in a cyclic sequence, the flue gases exhausting through the non-fired shaft(s), thereby effecting heat recovery. They generally have very good specific fuel consumption, but are more costly in electrical requirements due to the need for air blowers, rather than fans. There follows a resume of the currently available double shaft kilns.

the problems of increased bed resistance to gas flow with smaller sized stone. They employ the technique of regenerative flow, whereby two, or more, shafts are fired singly in a cyclic sequence, the flue gases exhausting through the non-fired shaft(s), thereby effecting heat recovery. They generally have very good specific fuel consumption, but are more costly in electrical requirements due to the need for air blowers, rather than fans. There follows a resume of the currently available double shaft kilns.

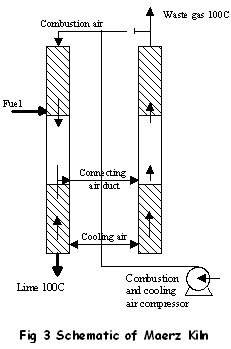

Maerz

The Maerz kiln design is probably accepted as the most successful double shaft kiln. Fuel is burnt in the upper end of the burning zone in one cylindrical shaft, and the hot gases flow co-currently with the charge in that shaft, and then via a connecting duct to the other shaft, where they flow counter-currently to the charge. The second shaft thus acts as a recuperator. After a given time, the roles of the shafts are reversed. It is claimed that since the flow of gases and stone are in the same direction in the burning zone, the risk of overheating the lime is reduced, and a softer burnt, more reactive lime results. The kiln designs come in two forms, a standard and a [GLOSS]finelime[/GLOSS] kiln. The finelime kiln, which is a later development of the standard design, has a smaller rated capacity for any given geometric size relative to the standard kiln, and contains more refractory. Fig 3 shows a schematic of the kiln system.

Cimprogetti

The Cim-Reversy kiln operates in a similar manner to the Maerz kiln, but is formed from two D shaped chambers, flat sides adjacent, which gives a very short gas transfer duct, thus reducing the propensity for dust settling and deposition. These kilns have also been designed for small stone operation.

Voest-Alpine

The Valec kiln is a double shaft design using cylindrical shafts in the same manner as the Maerz design.

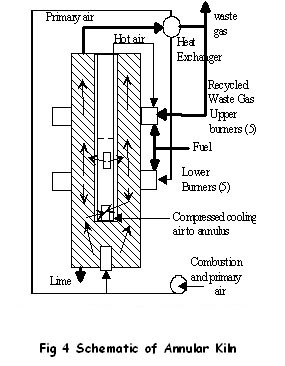

5. Annular Kilns

Annular kilns have been developed in Germany as an alternative method of ensuring even  heat distribution. The calcining and burning zones have an annular cross-section, and the preheating zone is circular. Figure 4 shows a schematic of this type of kiln system. Rheinische Kalksteinwerke (RKW) developed the original design, but they are generally available from Beckenbach and FLS.

heat distribution. The calcining and burning zones have an annular cross-section, and the preheating zone is circular. Figure 4 shows a schematic of this type of kiln system. Rheinische Kalksteinwerke (RKW) developed the original design, but they are generally available from Beckenbach and FLS.

There are two common versions of this type of kiln, in which the upper heat exchanger is optional. In the case where the kiln is equipped with two inner cylinders, see figure 5, the upper cylinder extracts ~30% of the flue gases to a recuperator to preheat the air for the lower level burners. The lower cylinder extracts gases at the bottom of the calcining zone for recirculation to the lower burners where combustion takes place in a vitiated air environment. The compressed air used for cooling in the annular sections of the cylinders is  subsequently used as primary air to the burners (lower cylinder) or for other purposes (upper cylinder). The upper cylinder is normally omitted from the design if the stone is wet as all the flue gases are then used for drying.

subsequently used as primary air to the burners (lower cylinder) or for other purposes (upper cylinder). The upper cylinder is normally omitted from the design if the stone is wet as all the flue gases are then used for drying.

Beckenbach

Most of the kiln shaft has an annular cross-section with five gasified fuel entry ports at each of two levels in the kiln, and staggered so as to deflect the charge as it falls in the outer annular space. Some of the waste gases go up the central cylinder space together with air from the cooling zone, and this can be deflected back to the lower burners and thus regulate the temperature.

Fig 5 Double cylinder annular kiln

6. Inclined Kilns

There are two types of inclined kilns, which have been developed to cater for small stone.

Double Incline

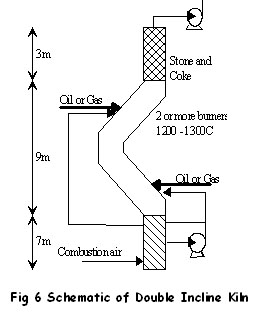

The double incline kiln was developed by Warmestelle, Steine und Erde Gmbh, and is now made by Beckenbach. The principal is to lengthen the burning zone, producing a milder flame, with more even heat distribution and transfer without the need for flue gas recycle. The kiln cross-section is rectangular, widening for two firing chambers. Considerable care is needed in selection of the refractory lining, due to the complex geometry. Waste gas and dust losses tend to be high, but the material residence time is typically about half of a conventional shaft kiln. Fig 6 shows a schematic of the kiln system.

The double incline kiln was developed by Warmestelle, Steine und Erde Gmbh, and is now made by Beckenbach. The principal is to lengthen the burning zone, producing a milder flame, with more even heat distribution and transfer without the need for flue gas recycle. The kiln cross-section is rectangular, widening for two firing chambers. Considerable care is needed in selection of the refractory lining, due to the complex geometry. Waste gas and dust losses tend to be high, but the material residence time is typically about half of a conventional shaft kiln. Fig 6 shows a schematic of the kiln system.

IAF Multi-Chamber

The IAF multi-chamber kiln was first built in 1972, and an improved design was introduced in 1987. The kiln is basically rectangular in cross-section, but is stepped into a number (4 to 6) of combustion chambers through the burning zone, which allows a degree of control of combustion conditions to suit the burning requirements of the stone.

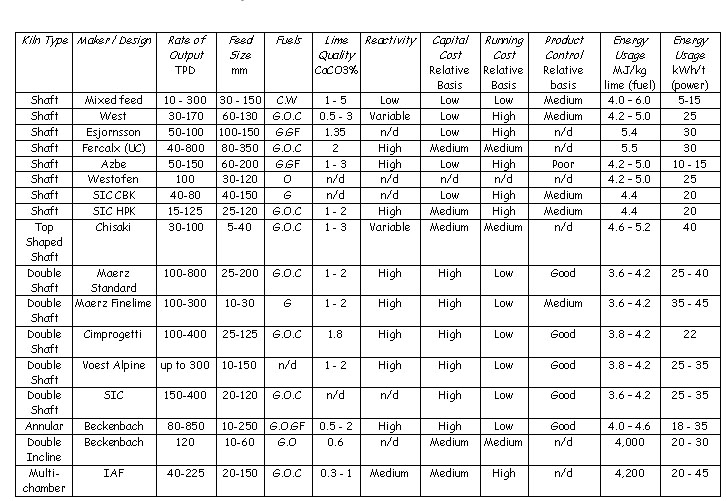

7. Summary of typical shaft kiln characteristics

G – gas; O – oil; C – coal/coke; W, – wood; GF – gasified fuel

Sources

[1] Oates J A H, Lime and Limestone, Chemistry and Technology, Production and Uses, Wiley-VCH, 1998, ISNB 3-527-29527-5

[2] Boynton R S, Chemistry and Technology of Lime and Limestone, John Wiley & Sons, 1980, ISBN 0-471-02771-5

[3] Wingate M, Small Scale Lime Burning, Intermediate Technology Publications, 1985, ISBN 0-946688-01-X