-

How do I measure pulverised coal devolatilisation in an oxy-fuel atmosphere using IPFR?

Date posted:

-

-

-

Post Author

Giovanni Coraggio

-

1. Background

Detailed knowledge of the fuel characteristics is essential for burner and boiler design (see CF48 and CF120). The use of advanced drop-tubes, such us the IFRF’s [GLOSS]Isothermal Plug Flow Reactor[/GLOSS] ([GLOSS]IPFR[/GLOSS]) and the IEN [GLOSS]Drop Tube Furnace[/GLOSS] ([GLOSS]DTF[/GLOSS]) to characterise solid fuels provides essential information (CF135). The behaviour of these fuels is strongly dependant on the heating rate, temperature and chemical composition, and in the IPFR and the DTF all these parameters are very similar to those found in industrial boilers and furnaces.

In the last decades, IFRF has carried out the characterisation of many solid fuels in the IPFR and the results are collected in the IFRF Solid Fuel Database[1]. In particular it has been used to measure [GLOSS]devolatilisation[/GLOSS] (CF183) and char combustion (CF184).

The development of [GLOSS]oxy-combustion[/GLOSS] with [GLOSS]RFG[/GLOSS] has created a new requirement for information about the differences in the combustion phenomena between conventional firing and oxy/RFG firing. In the last four years, within the framework of the EU-cofunded RELCOM project (www.relcomeu.com), IFRF and IEN used their drop tubes to measure devolatilisation in oxy-fuel atmospheres for three different coals at different temperatures in order to investigate the influence of the oxy-atmosphere.

2. Devolatilisation measurement procedure

The devolatilisation rate in an oxy-combustion environment can be characterised in a drop tube reactor like the IPFR by adjusting the atmosphere in the reactor and in the pulverised coal carrier gas flow in order to replicate the typical conditions of oxy-combustion with RFG but with no O2. As for conventional combustion, it is important to keep the O2 concentration as low as possible in order to minimize the influence of combustion reactions.

In the IFRF Isothermal Plug Flow Reactor these conditions are reached by feeding the pre-combustor burner with only pure oxygen and CO2 and trying to minimise the O2 excess in the flue gases. In addition, CO2 is used as the carrier gas for coal transport instead of N2.

The rest of the procedure is exactly the same as for other devolatilisation tests (CF135; CF183): the samples of the devolatilised coal for different residence times and temperatures are collected at the end of the tube, analysed and with the [GLOSS]ash-tracer method[/GLOSS] the conversion rate is calculated.

3. Characterisation procedure optimisation

Since the main physical parameters influencing the devolatilisation rate are the particle heating rate and the final temperature, IFRF wondered if there would be any effect caused by different chemical compositions of the combustion environment. This led to an investigation into a possible optimisation of the characterisation procedure by using an oxy-combustion environment only in the carrier gas or just using the conventional characterisation procedure.

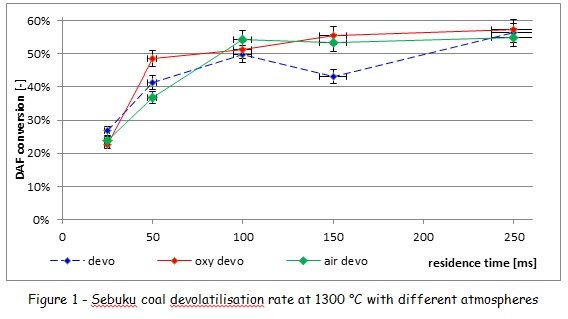

Figure 1 (IFRF Report nr. F112/y/01, [2]) shows a comparison between the devolatilisation results of Indonesian Sebuku coal at 1300 °C using different procedures:

· oxy-combustion atmosphere in the reactor and carrier gas (oxy devo)

· oxy-combustion atmosphere only in the carrier gas (devo)

· conventional air combustion atmosphere in carrier gas and reactor flow (air devo).

The different compositions are shown in Table 1.

Considering the normal uncertainties in this type of measurement, no significant differences were found in the IFRF tests.

Figure 1 – Sebuku coal devolatilisation rate at 1300 °C with different atmospheres

| Reactor gas composition | Carrier gas | ||

O2 | CO2 | H2O | | |

Devo | 0.1% | 10.0% | 18.3% | CO2 |

Oxy devo | 0.1% | 78.0% | 22.0% | CO2 |

Air devo | 0.1% | 10.0% | 18.3% | N2 |

Table 1 – Gas composition of the reactor for different atmospheres

3. Conclusions

The results of the IFRF RELCOM studies showed that the characterisation of devolatilisation in oxy-fuel atmospheres using the IPFR can be carried out not only by setting an oxy-atmosphere in the reactor and in the carrier gas but also by using an oxy-atmosphere only in the carrier gas, or by using the same procedure as conventional combustion.

As a consequence, all previous devolatilisation characterisation results obtained using the IFRF’s IPFR for conventional combustion (like the ones in the [GLOSS]IFRF Solid Fuel Database[/GLOSS]) can also be used for oxy-combustion with no significant increase in the uncertainties of the data.

It must be noted that other experiments in the RELCOM project using different facilities measured a difference in the devolatilisation rates between oxy and conventional combustion atmospheres. It is therefore recommended that a check test is done under the three conditions discussed above before using ‘air devo’ type data in an oxy-coal or oxy-fuel combustion simulation.

Sources

[1]IFRF Solid fuel database – www.ifrf.net – http://sfdb.ifrf.net

[2] G. Bonvicini, G. Coraggio, M. Faleni, Coal characterization in oxy-firing conditions using the Isothermal Plug Flow Reactor. Part 2 – Experimental results, IFRF Doc. No F112/y/01, Livorno, Italy, 2013.

Acknowledgements

The preparation of this Combustion File was supported by RELCOM; Reliable and Efficient Combustion of Oxygen/Coal/Recycled Flue Gas Mixtures – a project undertaken with the financial support of the European Commission under FP7 Grant Agreement Number 268191.