-

Vattenfall investigates sale of Magnum power plant in the Netherlands

Date posted:

-

-

-

Post Author

Greg Kelsall

-

-

![]()

Swedish power company Vattenfall has reported that it will investigate the sale of its 1.32 GW Magnum natural gas fired combined cycle gas turbine (CCGT) power plant. The power plant was originally designed as a coal gasification installation, but eventually built as a gas-fired power station with three steam and gas turbines. The ‘H2M’ (Hydrogen to Magnum) project there is a collaboration between Nuon, Equinor and Gasunie to convert one of the three 440 MW CCGT units of the Magnum power plant, located in Eemshaven, near Groningen in the Netherlands, to hydrogen. Equinor will provide an autothermal reformer (ATR) plant, where hydrogen will be produced from natural gas that is imported from Norway, with the carbon dioxide being captured. The H2M concept, as shown below, is to integrate a salt cavern to enable system flexibility, with the captured CO₂ shipped back to Norway and stored offshore.

![]()

H2M project concept

The sale will allow Vattenfall to focus its conventional operations on gas-fired power plants with a specific role in heat supply, with the potential revenue from the sale used for investments in renewable energy production such as offshore wind. According to the press release, the plant is expected to be needed for at least another 20 years, so continuity of business operations and employment are therefore not in question.

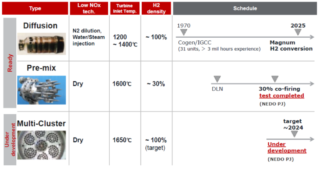

By way of background, a feasibility study for the H2M project has been successfully completed. A key component of the study was conversion of the plants M701F gas turbine supplied by Mitsubishi Power to burn 100% hydrogen by 2025. The combustion system options for this include relatively conventional diffusion flame combustion with NOx control achieved using nitrogen/steam/water diluent injection, or a concept under development utilising a ‘multi-cluster’ combustor, with the development paths shown below. The expectation is that to meet the H2M project timescale, the diffusion approach with diluent injection will be adopted.

![]()

H2M combustion system development

Looking at the two concepts in a little more detail:

Diffusion combustor – Air and fuel are injected into the combustor and burn with a stoichiometric flame. A high flame temperature is therefore achieved, resulting in relatively low levels of thermal NOx, requiring steam, water or nitrogen injection to reduce the flame temperature. This has the advantage of producing very stable combustion across a relatively wide operating range, with good tolerance to fuel property variation and no issues of flashback or combustion system dynamic pressure variations (as found in lean premix combustion systems). The downside is some loss in gas turbine efficiency due to diluent injection and potential blade erosion issues where water injection is used.

Multi-cluster combustor – The higher the concentration of hydrogen, the higher the risk of flashback becomes in industry-standard LPM combustor designs due the high flame speed of hydrogen. To reduce this risk, it is necessary to mix the air and fuel as quickly as possible. Mitsubishi Power have therefore devised a mixing system that disperses the flame and injects the fuel more finely. This multi-cluster design has a much greater number of fuel injection nozzles than the eight injection nozzles in the conventional DLN combustor. With such an approach, it is possible to mix air and hydrogen at a smaller scale without using swirling flow, which may allow for the compatibility of high flashback resistance and low NOx combustion.