-

GE wins US funding to develop hydrogen applicable gas turbines at 67% combined cycle efficiency

Date posted:

-

-

-

Post Author

Greg Kelsall

-

GE Gas Power announced recently that it has secured $4.2 million in federal funding from the US Department of Energy’s Advanced Research Projects Agency-Energy (ARPA-E). The funding is part of the ARPA-E OPEN 2021 programme, which prioritises the advancement of transformational technologies supporting a more decarbonised energy system. The funding is focused on two projects entitled ‘Lifted-flame combustion for high-hydrogen reheat gas turbines’ and ‘Manufacturing high-yield investment castings with minimal energy’. Both initiatives will be led by GE at its Global Technology Center in Greenville, South Carolina in the United States. As part of these projects, GE will carry-out research on gas turbine decarbonisation in close collaboration with industrial companies and educational institutions, including Georgia Institute of Technology (Georgia Tech), GE’s own Global Research Center, and DDM Systems, a pioneering company in the investment casting industry.

“As one of the world’s leaders in combustion technology, GE Gas Power is leading technology and manufacturing advancements in the power generation industry to enable low or zero-carbon power generation, all of which fundamentally relies on conducting advanced research both at GE and with collaborators,” said John Intile, Vice President, Engineering at GE Power. “GE is pleased that ARPA-E has recognised the value of developing alternative methods to boost the efficiency of gas turbines powered by fuel blends with high percentage of hydrogen, and the potential to completely disrupt current cycle time, producibility limits and energy requirements for investment castings of turbine components”.

Lifted-Flame Combustion for High-Hydrogen Reheat Gas Turbines

GE and its partners will investigate a novel ‘lifted-flame’ combustion approach for advanced gas turbine engines powered by mixtures of natural gas and hydrogen. Gas turbine combined cycle (GTCC) combustion technology is very mature in its present form and further gains in efficiency are likely to be incremental without game-changing technical and operating cycle advances. This new technology and research aim to break the current, materials-limited upper bound efficiency barrier for new gas turbines and installed base retrofits. According to GE, it will create a GTCC growth trajectory targeting net plant efficiencies of 67% or higher on a wide range of fuel compositions, while meeting strict emissions standards.

“Our goal of increasing gas turbine combined cycle plant efficiency by 5 or more percentage points in the next decade will position GE’s technology to help lead the energy transition,” said Jeffrey Goldmeer, Emergent Technologies Director for Decarbonization at GE Gas Power. “The proposed technology offers transformative value for both high-hydrogen and post-combustion carbon capture applications, ensuring dispatchable power with significantly reduced carbon emissions via highly efficient gas turbine-driven power generation.”

This targeted increase in efficiency is significant and would push GTCC efficiencies even higher than the current state-of-the-art at around 63%, offered by GE together with its competitors Siemens and Mitsubishi.

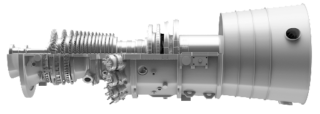

GE’s 9HA gas turbine (further details in fact sheet)

According to GE, in a lifted-flame system, the flame in the combustor is not attached to the injector. The method can reduce emissions but presents other challenges that this research hopes to overcome. Exact details of the combustion technology are not described by GE. The key development target will however be to maintain sub-25 ppm NOx emissions as the gas turbine firing temperature pushes to 1600-1700°C. At these temperatures, the industry standard lean-premix combustor technology approach is reaching its limits, particularly for high hydrogen fuels.

The project will be executed at GE’s Gas Turbine Technology Center in Greenville, South Carolina, home to the world’s largest gas turbine manufacturing facility and full-scale combustion test facility. The foundational testing of the technology will be conducted at the Atlanta-based Georgia Tech, a leading research university in the field of engineering and gas turbine combustion.

“As home to the largest university-based hydrogen research and development effort in the country, we are delighted to be collaborating with ARPA-E and GE Gas Power on this effort,” said Tim Lieuwen, Regents’ Professor and Executive Director of the Strategic Energy Institute at Georgia Tech. “We will be deploying state-of-the-art diagnostics and modelling tools to predict key hydrogen flame parameters and relating those to macro-engine performance.”

Manufacturing High-Yield Investment Castings with Minimal Energy

This second project will develop and combine key elements of casting technology including an innovative furnace development, as well as 3D printed additive ceramic mould technologies that will fundamentally change the production of high-value metal components for gas turbines. The new system could produce cast parts using up to 90% less energy than traditional methods, as well as provide improved quality, consistency, and yield, all at lower cost.

“The highly diverse energy mix of the future will demand that we are more flexible and responsive than ever before to fulfilling our customer needs for gas turbine components. The proposed system of technologies, combining digital tooling, cutting edge additive ceramic mould printing, and lean flow casting technology, will enable us to respond rapidly while reducing our energy usage and carbon footprint,” said Tom Amond, Emerging Technology Incubator at GE Gas Power.

GE Gas Power will develop this advanced solution in collaboration with DDM Systems, a company known for the precision investment castings of complex engineered components, with technical support from the GE Global Research Center in Niskayuna, New York.