-

Furnace and reactor digital twin offering to IFRF members

Date posted:

-

-

-

Post Author

Greg Kelsall

-

-

![]()

Bernhard Peters is Professor of Thermo-/Fluid Mechanics at the University of Luxembourg, an academic member of the IFRF through its Associate Member Group (AMG). He leads the Extended Discrete Element Method (XDEM) research group within the Department of Engineering, where he and his team have been developing digital twin technology for solid fuel furnaces and reactors based on advanced multi-physics.

Professor Peters now wants to offer his modelling capability and expertise to the IFRF industrial community and has provided me with the following flyer to share with potential interested users via our MNM Newsletter. If anyone is interested in finding out more, please contact Professor Peters directly at bernhard.peters@uni.lu or via the IFRF Administration team.

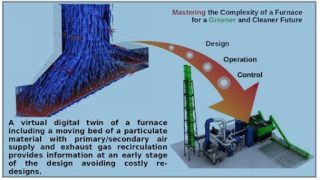

Cutting edge technology for solid fuel furnaces and reactors

A fiercely competitive market increases the pressure for faster and innovative technologies. This is achieved by a shift from an empirical-based practice to digital twin technology. The advanced simulation software XDEM as an advanced multi-physics simulation platform distinguishes itself from currently available technologies by representing the movement and thermodynamics of real particles that exchange mass, heat and momentum with a fluid, eg. gas. This cutting-edge technology was integrated into an easily manageable work flow and makes this technology available for both small and medium sized enterprises. A comfortable user interface allows carrying out all the steps required for a full three-dimensional simulation of a for example biomass furnace from input to final report. Innovative algorithms promote acceptable simulation times at very moderate computational resources.

Applying the above-mentioned technology allows creating a digital twin already at the very start of a project, providing crucial information for design and operation that increases significantly the potential for innovative ideas. Thus, problems are identified before they even occur, down-times are prevented and new opportunities and future businesses are developed. Hence, a dramatically faster rate for time-to-solution and time-to-discovery is achieved.

In addition, limitations of physical prototyping eg cost, time and conservative designs are removed, because a digital twin contributes to a reduced number of expensive physical prototypes in conjunction with a shorter testing phase. It often avoids redesigns because information is already available at an early stage of the development process.

The technology is maintained and supported professionally by Wikki GmbH, who’s expertise lies in providing services around OpenFOAM®. FOAM is an open-source C++ library to solve computational continuum mechanics problems with special emphasis on fluid dynamics.