-

BioIron steel plant receives $143 million investment from Rio Tinto

Date posted:

-

-

-

Post Author

Greg Kelsall

-

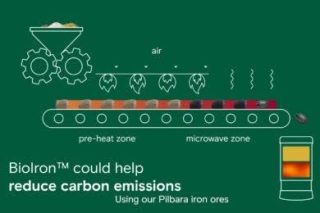

Rio Tinto is investing US$143 million in a new low-emissions steel research and development facility in Western Australia to assess a new ironmaking process. Named BioIron™, the process uses raw biomass and microwave energy instead of coal to convert iron ore to metallic iron in the steelmaking process. By using renewable electricity, together with ‘near-zero emission’ fuel from fast-growing biomass, BioIron has the potential to reduce carbon emissions by up to 95% compared with traditional blast furnace ironmaking.

The BioIron facility will include a pilot plant an order of magnitude larger than the initial pilot plant used in Germany, marking the first time that BioIron has been tested at a semi-industrial scale.

Raw biomass such as agricultural by-products including wheat straw, barley straw, sugarcane bagasse, rice stalks, and canola straw are used as the reducing agent in the steel making process instead of coal. The process needs these relatively high-lignocellulosic ’waste biomass’ materials and so does not compete with biomass used for food crops such as corn and sugar.

The biomass in briquette form is blended with iron ore and heated by a combination of combusting pyrolysis gases released by the biomass and high-efficiency microwaves that can be powered by renewable electricity. One main attraction of the BioIron process is that it uses less than a third of the electricity needed by other new technologies currently being trialled, such as those using hydrogen.

The pilot plant will be capable of producing one tonne of direct reduced iron per hour and will provide data for Rio Tinto to continue scaling the technology to a larger demonstration plant. It has been designed in collaboration with University of Nottingham in the UK, Metso Corporation in Finland and the Western Australian engineering company, Sedgman Onyx.

Fabrication of equipment for the plant and research facility will begin this year, with the facility to be commissioned some time in 2026.